Transparent stone powder is a high-performance functional filler material primarily composed of composite silicates. It features excellent transparency, high hue, good hardness, high gloss, strong collapse resistance, and low dust emission. Due to its exceptional properties, transparent powder plays a vital role in various industries, particularly in new materials and high-end manufacturing.

What is transparent stone powder?

Transparent stone powder, also known as transparent functional filler powder, is a composite silicate powder produced through a fine grinding process. Its raw materials are primarily transparent or translucent minerals, such as quartz, corundum, beryl, and topaz, which exhibit excellent light transmittance and high hardness. The resulting transparent powder not only retains the physical properties of the original mineral but also offers enhanced processing adaptability and versatile filling properties.

Raw Material Analysis: Transparent Stone and Its Types

Transparent stone generally refers to transparent or translucent mineral raw stone, primarily including the following two categories:

Natural stone: such as transparent or translucent marble (beige series, rosin yellow, lemon yellow, white crystal, etc.), exhibits a certain degree of light transmittance and is commonly used in the construction and decoration industries.

Artificial synthetic stone: Synthetic stone created by adding resins, minerals, and pigments. Artificial transparent stone offers advantages such as high controllability and mass production capacity, making it widely used in commercial building decoration.

Quartzite is the most common type of transparent stone. Its primary component is low-temperature quartz (α-quartz), a widely distributed and stable rock-forming mineral. Quartzite, a metamorphic rock primarily composed of quartz, is suitable for producing high-purity transparent powder.

Applications of Transparent Powder

Transparent stone powder is widely used in the following areas:

Building Materials: Used in artificial stone, artificial floor tiles, fire-resistant ceilings, linoleum, and other building materials to enhance the material's texture and strength.

Industrial: Used as a reinforcing or transparent filler in industries such as plastics, rubber, composite materials, electrical insulation, and glass.

Chemicals and Daily Chemicals: Used as a filler in products such as paints, coatings, inks, cosmetics, and toothpaste, enhancing their texture and performance.

Pharmaceuticals and Textiles: Used as a drug carrier or textile additive to improve functionality and stability.

Transparent Stone Powder Grinding Process and Equipment Selection

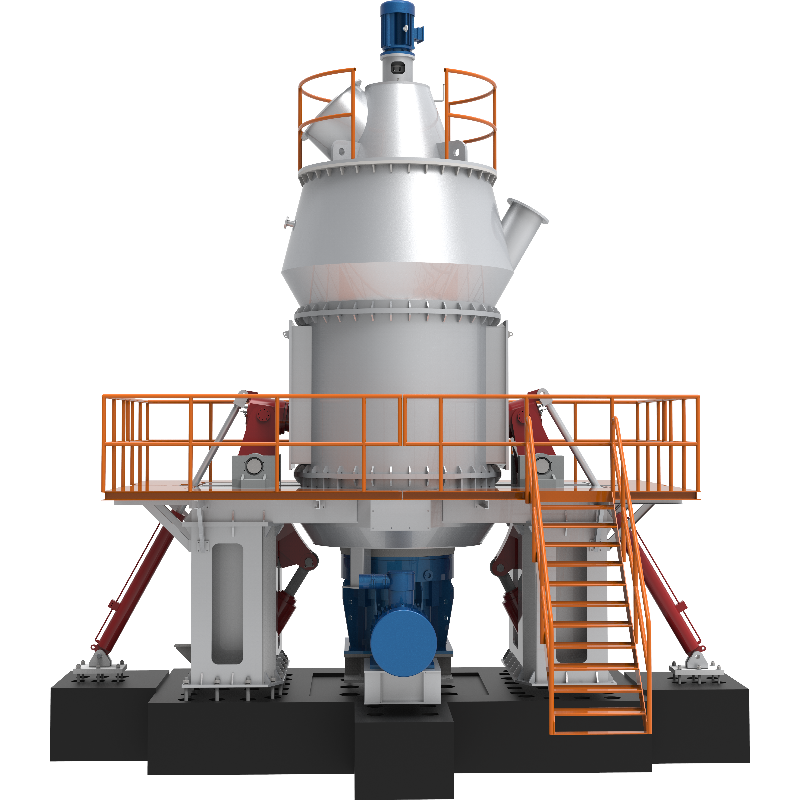

The production of transparent stone powder typically requires efficient grinding equipment. A grinding production line primarily consists of a crusher, elevator, storage silo, main grinding machine, analyzer, piping, and powder collector. Depending on the hardness, moisture content, and target particle size of the raw material, different mill types can be selected, including Raymond mills, vertical mills, high-pressure mills, and micro-powder mills.

Grinding processes offer the following advantages:

High degree of automation: Reduces manual labor and labor costs.

Energy saving and environmental protection: New equipment offers high energy efficiency, low dust levels, and complies with environmental standards.

High production efficiency: The entire line boasts high production capacity, adapting to large-scale industrial needs. Uniform Particle Size: Precise fineness control meets the powder requirements of various applications.

Market Trends and Equipment Selection Recommendations

With the rapid development of industries such as artificial stone, high-performance plastics, and environmentally friendly coatings, the market demand for transparent powder continues to grow. At the same time, intensified industry competition has led to frequent price fluctuations in transparent stone powder mill equipment. The technology, configuration, and after-sales service of different manufacturers all affect the equipment price and operating costs.

When selecting a transparent stone powder mill, users are advised to select the appropriate equipment model based on their production capacity requirements, raw material type, and product positioning, and consider the manufacturer's technical support and project experience.

Conclusion

As a high-performance filler material, transparent stone powder has demonstrated strong application potential in various fields. From raw material selection to grinding process design to product application expansion, the transparent powder industry chain is continuously developing towards high efficiency, environmental protection, and intelligent technology. When planning related projects, companies should focus on scientific equipment configuration and professional technical support to achieve sustainable and high-quality industrial upgrading.

To learn more about the configuration of transparent stone grinding equipment and production line projects, please contact Cronus' professional technical service team for one-on-one consulting support.