Ball Mill Product Introduction

Ball mills are key equipment for pulverizing materials after crushing. They are widely used in the production of cement, silicate products, new building materials, refractories, fertilizers, ferrous and non-ferrous metal beneficiation, glass, and ceramics. They perform dry or wet grinding of various ores and other grindable materials.

Note: Without the addition of water, a ball mill produces a dry powder, also known as a dry ball mill. When water is added during the beneficiation process to produce a slurry, it is also known as a wet ball mill.

Cronus has a large customer base and boasts a comprehensive sales team, a strong installation team, and a dedicated after-sales service team. We are committed to ensuring a worry-free purchase and helping your business flourish.

How a Ball Mill Works

The material is fed from the feed device through a hollow feed shaft and evenly fed into the first chamber of the mill. This chamber features stepped or corrugated linings and contains steel balls of varying sizes. The centrifugal force generated by the rotating drum carries the balls to a certain height, where they fall, impacting and grinding the material. After coarse grinding in the first chamber, the material passes through a single-layer partition wall into the second chamber, which features flat linings and steel balls for further grinding. The powder is discharged through the discharge grate, completing the grinding process.

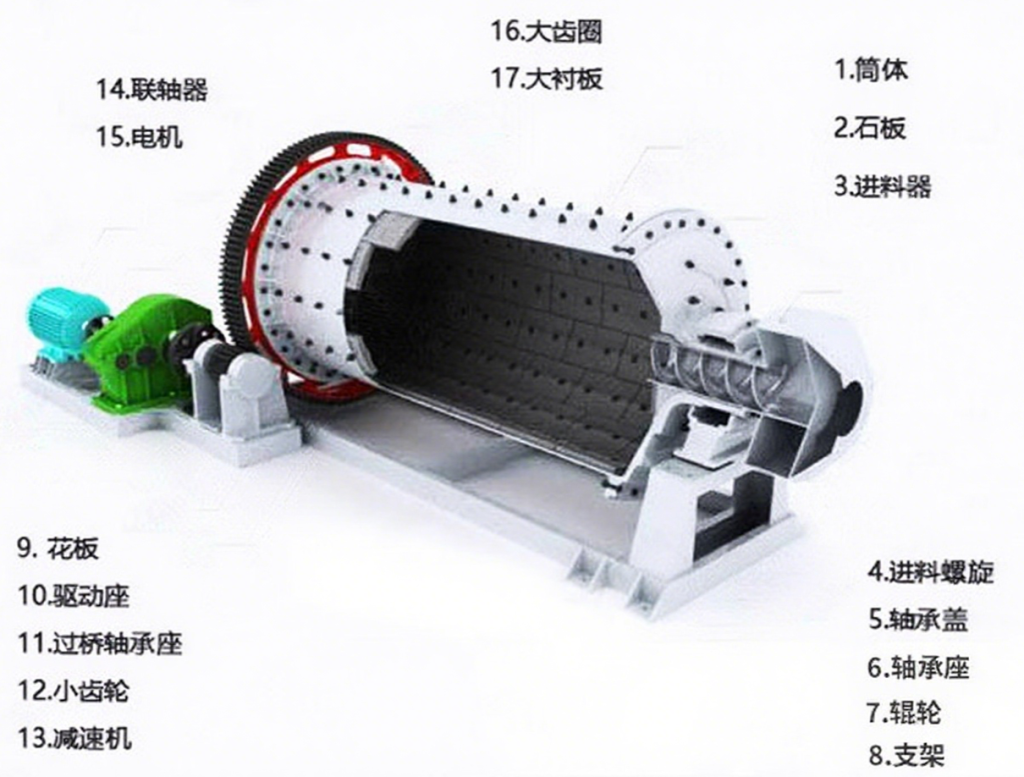

Ball Mill Structural Features

A ball mill consists of a feeder, discharger, rotary unit, and transmission unit (reducer, small transmission gear, motor, and electronic control). The hollow shaft is made of cast steel with a removable inner lining. The large rotary gear is hobbed from a casting, and the drum is lined with wear-resistant liners, providing excellent wear resistance. This ensures smooth operation and reliable performance. Depending on the material and discharge method, dry-type ball mills and wet-type grate-type ball mills can be selected.

Ball Mill Internal Structure Diagram

Ball Mills Factory Direct, Affordable Prices

Ball mill prices have always been a major concern for users. Market quotes for this equipment are generally not clearly stated. This is because different manufacturers, manufacturing methods, purchasing channels (direct from the manufacturer or from a distributor), material selection, and model variations all contribute to the ball mill's pricing. Small ball mills are generally less expensive. For specific equipment quotes, customers should consult the manufacturer directly. As a professional ball mill manufacturer, Cronus offers reliable and competitive equipment quotes, making it your best choice for affordable ball mills. For detailed pricing, please feel free to contact us.

Cronus Ball Mill Factory Workshop (Direct Shipping from Ready Stock)

Ball Mill Wear Parts

Ball mill wear parts primarily refer to the liner. Liner wear and service life are crucial to the cost and performance of the ball mill. So, how can you distinguish the quality of a liner? Three key factors should be considered: first, the liner's casting and smelting process; second, whether the liner's quenching and tempering treatments are up to standard; and finally, the liner's material. Common liner materials on the market include high-chromium cast iron, low-alloy wear-resistant cast steel, and high-manganese steel. All three materials offer excellent wear resistance. Cronus welcomes you to visit our factory to learn about our ball mill and its liner production process.

Ball mill consumable parts, left liner, middle steel ball, right steel forging

Cronus is dedicated to mineral processing technology research. With mature production concepts and a professional R&D team, we create high-quality ball mill equipment for you! Our experienced technical engineers also provide you with mineral processing plant design technology and mineral processing equipment process configuration solutions, making it an excellent choice for your mineral processing plant investment!

Industrial Ball Mill Specifications

| Model | Cylinder Speed (r/min) | Ball Loading (t) | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kw) | Total Weight (t) |

|---|---|---|---|---|---|---|---|

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | Determined by process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | Determined by process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | Determined by process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

Note: Specifications may vary depending on material characteristics and operational conditions. All measurements are approximate and subject to change without notice.