On July 2, 2025, Cronus successfully completed the packaging and shipment of four customized bucket elevators from its manufacturing facility. These units are now en route to Nigeria, where they will be integrated into a local mining company's bulk material handling system.

The equipment delivered in this shipment features Cronus' latest sealed high-efficiency bucket elevator design, engineered for smooth operation, high lifting efficiency, and easy maintenance. Widely used across industries such as mining, building materials, chemicals, and agriculture, the elevators are tailored to lift powdered, granular, and small lump materials vertically.

🏗️ Product Overview: Cronus Bucket Elevator

Bucket elevator is suitable for lifting materials from low to high positions in a continuous and automated process. Once materials are fed into the hopper via a vibrating table, the machine runs steadily to elevate the contents upward. Both the lifting height and conveying speed can be adjusted according to operational needs.

🔧 Bucket Elevator of Main Features

- Low Power Consumption

Utilizing inflow feeding, gravity or centrifugal unloading, and a tightly arranged large-capacity hopper design, the bucket elevator minimizes material return and excavation losses, significantly reducing energy usage. - Wide Application Range

It is suitable for transporting a wide variety of materials—from powders and small particles to more abrasive materials—thanks to its flexible design and excellent sealing, which also helps reduce environmental dust pollution. - Reliable Operation

Designed using advanced engineering and precision manufacturing, the equipment ensures long-term stable operation with a mean trouble-free period exceeding 20,000 hours. It also supports higher lifting heights due to smooth and stable conveying. - Extended Service Life

Inflow-type feeding minimizes collision and squeezing of materials. The buckets do not dig into the material pile, reducing wear and mechanical damage. The design ensures minimal spillage and maximized durability.

⚙️ Bucket Elevator of Working Principle

The bucket scoops material from a storage hopper below, lifts it vertically via belt or chain, and discharges it at the top through gravity or centrifugal force.

- In belt-driven elevators, rubber belts are mounted on drive and redirecting rollers.

- In chain-driven elevators, two parallel chains drive paired sprockets.

The whole system is enclosed in a casing to prevent dust emissions.

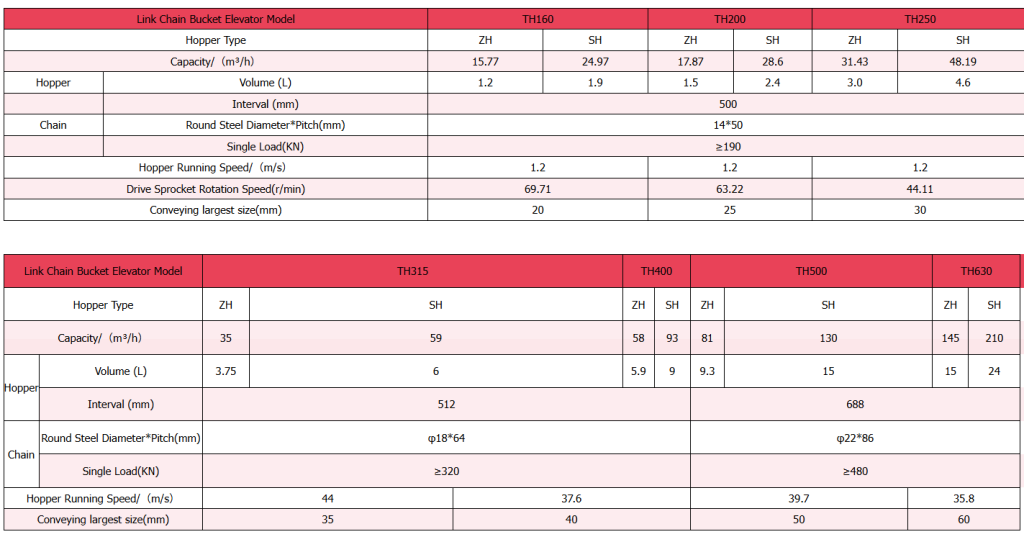

Bucket Elevator of Parameters

To ensure optimal performance under Nigeria's hot and dusty environmental conditions, the elevators were specially reinforced with upgraded drive components, enhanced dust-sealing structures, and an integrated motor-gearbox system. Every stage of production—from raw material sourcing and sheet metal fabrication to painting and final assembly—was executed under strict quality control in compliance with international standards.

Cronus' technical team worked closely with the Nigerian client throughout the project, providing engineering consultation, design customization, and remote technical support to guarantee smooth installation and commissioning upon arrival.

This successful delivery underscores Cronus' robust capabilities in the field of bulk material conveying equipment and reflects the company’s strategic progress in international markets. In recent years, Cronus has expanded its global footprint, exporting high-performance equipment to Southeast Asia, the Middle East, Africa, and South America.

With a commitment to “Quality First, Service Foremost,” Cronus will continue to invest in R&D, optimize product design, and deliver high-value solutions to industrial clients around the world.