The grinding and further processing of calcium oxide (CaO, commonly known as quicklime) typically requires high-fineness, high-efficiency grinding processes. Depending on the material hardness, fineness requirements, production capacity, and environmental requirements, commonly used mining grinding equipment includes the following:

Raymond Mill

The Raymond Mill is a traditional and cost-effective equipment suitable for medium-hardness calcium oxide materials. Its advantages include high efficiency and energy saving, increasing production capacity by 40% and reducing energy consumption by over 30% compared to traditional equipment. Its environmentally friendly design, equipped with a pulse dust collector, reduces dust emissions and meets environmental standards. Its compact structure and small footprint make it suitable for small and medium-sized production lines.

Applications: Fineness requirements range from 80-400 mesh, making it suitable for medium-scale calcium oxide further processing, such as in the preparation of building materials and chemical raw materials.

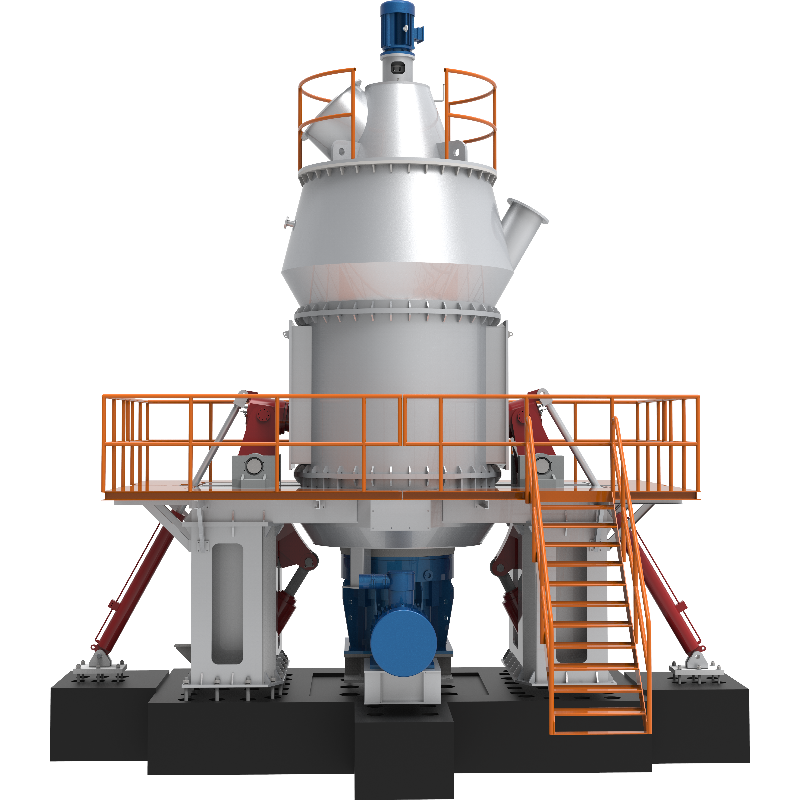

Vertical Roller Mill

Vertical Roller Mill is a large-scale equipment that integrates drying, grinding, grading, and conveying. Its advantages include low overall investment costs, occupying only 50% of the space required by a ball mill, and being suitable for outdoor installations. It also boasts high grinding efficiency, consuming 40%-50% less energy than a ball mill, and can process coarse to ultrafine powders (200-2500 mesh). It also boasts a high degree of automation, easy maintenance, and low operating costs.

Applications: Large-scale calcium oxide production lines, particularly suitable for ultrafine powder production, such as high-end building materials and pharmaceutical carriers.

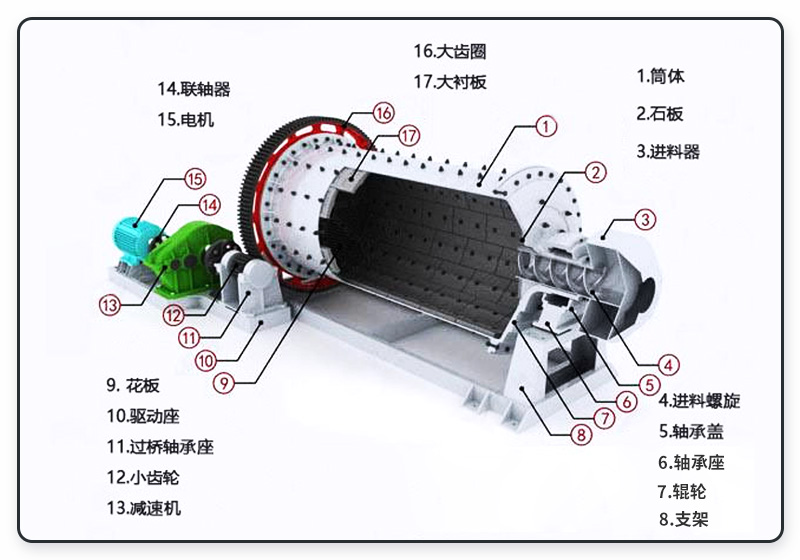

Ball Mill

A ball mill is a traditional grinding machine suitable for extensive processing of low- to medium-hardness materials. Its advantages include high output, low waste, and simple operation. It is also highly adaptable and can handle larger particles. However, it is noisy and requires significant space. Dust removal equipment may be required for environmentally sensitive applications.

Applications: Primary or medium-fine processing of calcium oxide (under 200 mesh) is suitable for applications where fineness requirements are less stringent, such as metallurgical fluxes and cement additives.

Equipment Selection Recommendations:

Productivity and Cost: Vertical mills are recommended for large-scale production, while Raymond mills are recommended for small- to medium-sized production.

Environmental requirements: Equipment equipped with a dust removal system, such as a Raymond mill or vertical mill, is preferred.

summary

the selection of a mill for further processing of calcium oxide powder requires a comprehensive consideration of product fineness, production capacity, budget, and environmental requirements. Raymond mills and vertical mills are the mainstream choices due to their high efficiency, environmental friendliness, and wide fineness adaptability, while ultrafine mills and air jet mills are suitable for high-end, fine-fining applications. It is recommended to work with the equipment manufacturer's engineers to customize a solution based on specific project requirements.