CRRM1850 large Raymond mill is a new generation of high-efficiency and energy-saving powder processing equipment independently developed by Cronus. Based on the traditional Raymond mill, the equipment has carried out structural optimization and technical upgrades, innovatively improved the design of the grinding roller and grinding system, effectively expanded the contact area between the grinding roller and the grinding ring, significantly enhanced the crushing capacity, and achieved a leap in the output and fineness of the product.

In addition, CRRM1850 has systematically optimized the core components, upgraded the main shaft transmission structure and the sealing performance of the grinding roller assembly, making the equipment operation more stable and reliable, and the maintenance operation more convenient and efficient. The whole machine is equipped with an intelligent pulse dust removal system to efficiently collect and process the residual airflow, and the operation site is clean and dust-free, meeting environmental protection standards.

Recently, a non-metallic mining enterprise in Anhui purchased a Cronus Raymond mill CRRM1850 for calcite grinding, with a target fineness of 300 meshes. At present, the equipment has been installed and debugged and put into production smoothly. Next, let us walk into the installation site together to see the actual situation of the project!

Composition and structure of Cronus CRRM1850 Raymond mill

CRRM1850 Raymond mill adopts advanced grinding technology, scientific and reasonable structural design, and the synergy of various components ensures efficient and stable powder processing. It is mainly composed of the following core components:

Grinding roller

The grinding roller is the core grinding component of CRRM1850, integrating grinding, fineness adjustment, efficiency enhancement, wear resistance, and uniformity. It grinds the material into powder by rotating and extruding, and can flexibly adapt to different fineness requirements by adjusting the pressure. It adopts high-hardness wear-resistant material, strong wear resistance and long service life. During the grinding process, the grinding roller is evenly stressed to avoid over-grinding or under-grinding of the material, ensuring that the finished product particle size is uniform and stable.

Grinding ring

The grinding ring and the grinding roller work together at high speed to complete the grinding and crushing of the material. Its main functions include:Solidly support the grinding roller to ensure that it rolls along a stable trajectory;

Form a rolling belt with the grinding roller to improve the grinding efficiency by squeezing and shearing the material at high pressure;Strong wear resistance, reduce maintenance frequency, and extend the service life of the equipment.

Shovel

The main function of the scraper is to scoop up the material entering the mill and evenly send it between the grinding roller and the grinding ring to ensure continuous and stable grinding. It is made of high-wear-resistant alloy material, with excellent wear resistance and suitable for processing high-hardness materials.

Classifier

The analyzer is used to accurately control the fineness of the finished product. By adjusting its rotation speed, the powder particle size (80~325 mesh) can be flexibly adjusted. The ground powder rises to the analyzer with the airflow, and the qualified fine powder enters the collection system, and the coarse particles fall back and are re-ground to ensure that the finished product fineness is stable and meets the standard.

Fan

The fan provides a stable airflow, blows the ground powder into the analyzer for sorting, and pushes the qualified fine powder into the collection system. Its air volume can be adjusted to meet the grinding needs of different materials.

Cyclone collector

The cyclone collector is used to efficiently separate and collect qualified finished powder, with a collection rate of ≥95%, ensuring no dust spillage and meeting environmental protection requirements.

Pipeline system

The pipeline system connects all components to ensure smooth airflow, reduce energy consumption and improve overall operating efficiency.

Working principle of CRRM1850 Raymond mill

CRRM1850 adopts an integrated process of "grinding-classification-collection" to ensure efficient, energy-saving and environmentally friendly powder production:

Coarse crushing first: large pieces of raw materials are coarsely crushed to ≤30mm particles by the crusher to provide suitable particle size for subsequent grinding.

Quantitative delivery: The electromagnetic vibrating feeder evenly and continuously feeds the material into the grinding area to ensure grinding stability.

Grinding and crushing: The grinding roller presses the grinding ring under the action of centrifugal force to form a high-strength rolling belt, and the material is crushed into fine powder by extrusion and shearing.

Grading and sorting: The powder enters the turbine classifier with the airflow, the coarse particles fall back and are re-grinded, and the qualified fine powder enters the collection system.

Efficient collection: The finished powder is separated and collected by the cyclone collector and can be directly packaged or enter the next process.

Functional characteristics of CRRM1850 Raymond mill

| Parameter | Specification |

|---|---|

| Production Capacity | 6.5~30 t/h (higher production capacity can be customized) |

| Fineness Range | 80~325 mesh (adjustable) |

| Max. Feed Size | ≤30 mm |

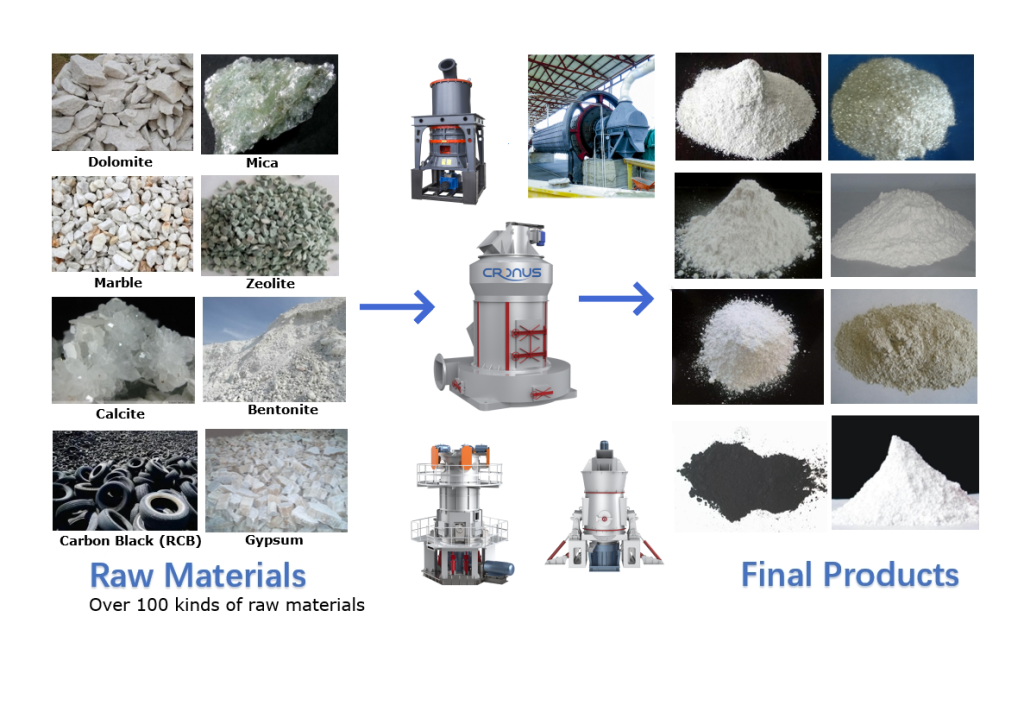

| Applicable Materials | Non-flammable & non-explosive ores (Mohs hardness ≤7, humidity <6%): |

| Calcium Carbonate: Limestone, Calcite, Marble | |

| Silicates: Potassium Feldspar, Bentonite, Kaolin | |

| Industrial Minerals: Barite, Gypsum, Talc, Fluorite Others: Coal Slag, Red Iron Oxide, Iron Ore, etc. |

Product advantages of CRRM1850 Raymond mill

Vibration reduction and noise reduction: The main machine adopts comprehensive vibration reduction technology, which runs smoothly, has low noise and extends the life of the equipment.

Structural innovation: Optimize the grinding chamber and transmission system, save more than 30% energy and improve production efficiency.

Heavy-duty reducer: shock-resistant and wear-resistant, supports electric/pneumatic control, and is easy to maintain.

Intelligent control: one-button start and stop, adjustable parameters, realize automated production, and reduce labor costs.

Fan optimization: equipped with adjustable damper, precise control of air volume and pressure, to ensure stable quality of finished products.

CRRM1850 Raymond mill is widely used in mining, building materials, chemical industry and other fields with its advantages of efficient grinding, intelligent control, energy saving and environmental protection. It is an ideal equipment for modern powder processing.