The Raymond Roller Mill is a type of grinding equipment suitable for producing various types of mineral powders and coal powder.

I. Applicable Materials and Applications

(I) Applicable Materials

Barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, etc.

(II) Applications

Metallurgy, chemical industry, building materials, mining, pharmaceuticals, cosmetics, and other industries.

II. Material Requirements for Raymond Roller Mills

- Mohs Hardness: 7 or less

- Moisture Content: 8% or less

- Non-flammable or explosive materials

- Feed Particle Size Range: 40-400 Mesh

III. Inquiries and Contacts

- Inquiry Hotline: +86-

- Related Sections: Contact Us, History, Equipment Components, Operating Principle, Equipment Advantages, Output

IV. History of Raymond Roller Mills

First Generation Raymond Roller Mills

In 1906, C.V. Grueber founded a machinery factory in the southern suburbs of Berlin. Using a patent obtained in the United States, he produced the first Maxecon Mill, which he used for coal grinding at the Moabit power plant, with a grinding capacity of 5 tons/hour. In the following years, nearly 600 units were sold for various applications.

At the same time, the Berlin Electric Company (BEWAG) planned to develop a coal mill with a higher output. When E.C. Loesche took over and led C.V. Gruber Maschinenfabrik, he decided to purchase the patent for the "Raymond Centrifugal Roller Mill" from the United States to produce the first generation of Raymond Roller Mill systems.

(III) Shanghai Cronus Launches Upgraded Raymond Roller Mill

Shanghai Cronus has developed and launched an upgraded Raymond Roller Mill to address the high energy consumption, low efficiency, and severe dust pollution issues of traditional Raymond Roller Mills. While maintaining the stability of traditional structures, this equipment utilizes a high-efficiency grading system and environmentally friendly dust removal devices, and all core components are reinforced with wear-resistant treatment. Its key features include:

- A 20%-30% increase in output and more precise fineness control;

- An intelligent electronic control system enables remote monitoring and automated operation;

- Stronger sealing throughout the machine significantly reduces dust leakage;

- A smaller footprint makes it suitable for large-scale application in small, medium, and large factories.

V. Expanding Application Areas of Raymond Roller Mills

(I) Papermaking Industry

Diatomaceous earth processed by a Raymond Roller Mill is commonly used as a filler in cigarette paper, filter paper, deodorizing paper, packaging paper, and decorative paper, reducing raw material usage and improving paper properties.

(II) Metallurgical Industry

In the metallurgical field, Raymond Roller Mills can be used in powder metallurgy, mechanical alloying, metallurgical raw material processing, metallurgical waste slag utilization, foundry sand, superhard materials, and solid lubricants.

(III) Building Materials Industry

The key components of the Raymond Roller Mill are manufactured from high-quality steel, and wearing parts are made of high-performance wear-resistant materials, ensuring stable operation during construction waste recycling.

(IV) Chemical Industry

Raymond Roller Mills can be used to process chemical powders such as gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black powder, coal powder, various rubber powders, and alum.

In addition, Raymond Roller Mills are suitable for small and medium-sized factories and are most efficient for processing materials with a Mohs hardness of 5 or below. Although it has some limitations, it is best suited for processing soft to medium-hard materials.

VI. Key Components of a Raymond Roller Mill

A Raymond Roller Mill consists of key components such as the grinding unit, classifier, reducer, star frame, and grinding roller assembly, as well as other vulnerable parts.

(I) Grinding Unit

Equipped with specialized grinding rollers and grinding rings, this unit primarily completes the grinding process. The crushed fine powder enters the classifier along with the classified airflow, where it is properly classified.

(II) Reducer

A power transmission mechanism that uses a gear transmission to reduce the motor speed, thereby generating greater torque.

(III) Star Frame

When the mill is operating, this unit is driven by the main shaft, which in turn drives the grinding rollers and grinding rings.

(IV) Grinding Roller Assembly

A group of components suspended from the star frame are also the core components of the Raymond Roller Mill and are also the most prone to failure. Lubricating oil should be added promptly.

VII. Working Principle of a Raymond Roller Mill

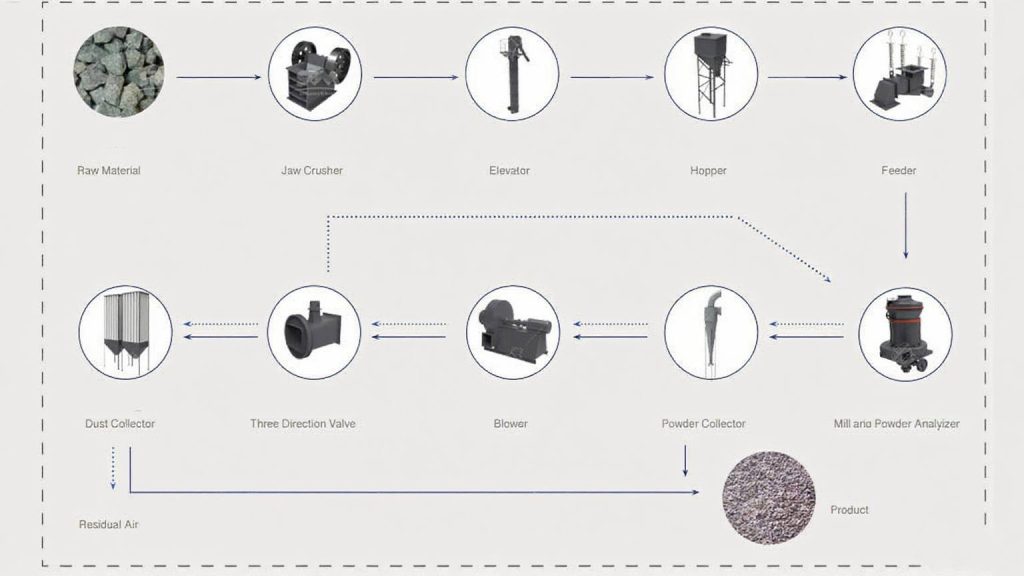

Large materials are crushed into smaller pieces by a jaw crusher and then fed into a hopper via an elevator. An electromagnetic vibrating feeder then delivers the crushed material evenly and quantitatively into the grinding chamber of the Raymond Roller Mill.

After grinding, the material is blown by air to a classifier for classification. The classifier's impeller drives material that doesn't meet the required fineness back into the grinding chamber for re-grinding. Powder that meets the required fineness is collected by a cyclone collector and discharged from the bottom as the finished product. The air then flows through the return air duct at the top of the cyclone collector into the fan. The entire system operates in a closed loop, operating under positive and negative pressure conditions.

Because the material contains a certain amount of moisture, the heat generated during the grinding process can cause moisture in the air to evaporate or expand within the grinding chamber, resulting in a sharp increase in air volume. Furthermore, if the feed inlet and pipe connections are not properly sealed, outside air may intrude into the mill, causing airflow imbalance. Therefore, Shanghai Shanmei has installed an exhaust valve at the fan outlet to direct excess air into a bag filter for purification before discharge. This design achieves both balanced airflow and environmentally friendly production.

VIII. Features and Advantages of Raymond Roller Mills

Grinding mills are highly efficient ultrafine grinding equipment, and the Raymond Roller Mill is a representative example. Once started, the mill allows for continuous feeding and discharging without interruption. Fineness can be adjusted using the fan and classifier. No screens are required, effectively preventing equipment blockage.

The Raymond Roller Mill integrates drying and grinding functions within the roller mill, eliminating the need for separate drying equipment, reducing capital investment, shortening processing time, and streamlining operations. As the most widely used and representative key equipment in the deep processing of non-metallic minerals, the Raymond Roller Mill offers particular advantages in energy conservation and environmental protection.

(I) Stable and Reliable Transmission

The main transmission utilizes a sealed gearbox and pulley, ensuring smooth and reliable transmission.

(II) High-Quality Component Materials

Key components are made of imported high-quality steel, and grinding components are constructed from high-performance, wear-resistant materials.

(III) High Efficiency and Energy Saving

The equipment occupies a small footprint and efficiently completes the powder production process, producing a uniform finished product fineness and a screening pass rate of up to 99%.

(IV) High Degree of Automation

The electrical system incorporates foreign centralized control technology, enabling unmanned operation and simplifying maintenance.

IX. How to Increase the Output of a Raymond Roller Mill?

- As large-scale crushing equipment, the jaw crusher is installed and tested under no-load conditions at the manufacturer's workshop, but it must be disassembled into its components for transportation.

- Perform routine maintenance on the Raymond Roller Mill.

- Proper Raymond Roller Mill operation is essential: Improper operation can damage the equipment, shorten its service life, and lead to significant economic losses due to prolonged downtime.

- Control the feed standards of the Raymond Roller Mill.

X. Future Development Trends of Raymond Roller Mills

The production process of a Raymond Roller Mill is generally "feeding - crushing - classification - powder collection," with classification and powder collection being the core steps. However, traditional grinding mills, due to their narrow blades and large impeller diameter, result in wide blade gaps. This leads to common problems such as low rotational speed, uneven internal and external linear speeds, poor sealing design, and ash leakage. This in turn results in low classification efficiency and a high rate of large particle leakage. Furthermore, the powder collection system of traditional Raymond Roller Mills is prone to dust spillage, impacting process quality and causing waste.

The improved Raymond Roller Mill has undergone upgrades in research and development, design, and manufacturing, particularly in key components: The use of more composite materials and thickening ensures greater compressive strength, corrosion resistance, and toughness. This not only improves the Raymond Roller Mill's production performance and quality, but also reduces the impact of dust and noise during production. More importantly, it achieves environmentally friendly production and alleviates environmental pollution.