Zambia, as the "copper mining country" of Africa, has abundant copper resources but diverse mining scenarios. There are both large-scale mining operations with large-scale production and flexible processing requirements for small and medium-sized mines. There are high demands for the wear resistance, adaptability, energy efficiency, and mobility of equipment. Cronus, relying on its mature experience in mining equipment research and manufacturing, can provide complete sets of equipment and customized solutions covering the entire process of copper ore crushing and screening. It precisely matches the processing characteristics of Zambia's copper ores (mostly sulfide copper ores, with high hardness and some associated magnetic impurities). Below are the details of the core equipment.

I. Crushing Equipment Series

The crushing process follows the principle of "more crushing, less grinding", aiming to reduce the energy consumption of subsequent grinding. Cronus offers a range of classification crushing equipment from coarse crushing to fine crushing, suitable for handling ores of different particle sizes.

Impact crusher (core equipment for coarse crushing)

As the preferred coarse crushing solution for Zambia's hard sulfide copper ores, the Cronus Jaw Crusher efficiently reduces large ore chunks (up to 1000mm) to a medium size of 200-300mm. Its compound swing design ensures a high crushing ratio (4-6) and robust processing capacity.

Key wear parts (jaw plates) are made of high-manganese steel for exceptional durability against abrasive ores. The crusher features a simple design with easy maintenance—primarily requiring periodic jaw plate replacement. This significantly lowers operating costs and reduces technical barriers, making it particularly suitable for small and medium-sized mines.

2. Cone crusher (core equipment for medium-sized crushing)

The Cronus Cone Crusher performs efficient medium crushing via the oscillating and squeezing action between its moving and fixed cones. It reduces coarse-crushed copper ore to a uniform 10–50mm particle size, ideal for subsequent fine crushing.

Equipped with multiple crushing chamber types, it can be flexibly configured to match ore hardness and specific mine output needs in Zambia. Operation is stable, delivering consistent product size with lower wear-part consumption compared to impact crushers, making it suitable for continuous high-hardness ore processing. Widely used in medium-sized beneficiation plants, its hydraulic adjustment system allows rapid output size changes, ensuring convenient and efficient operation.

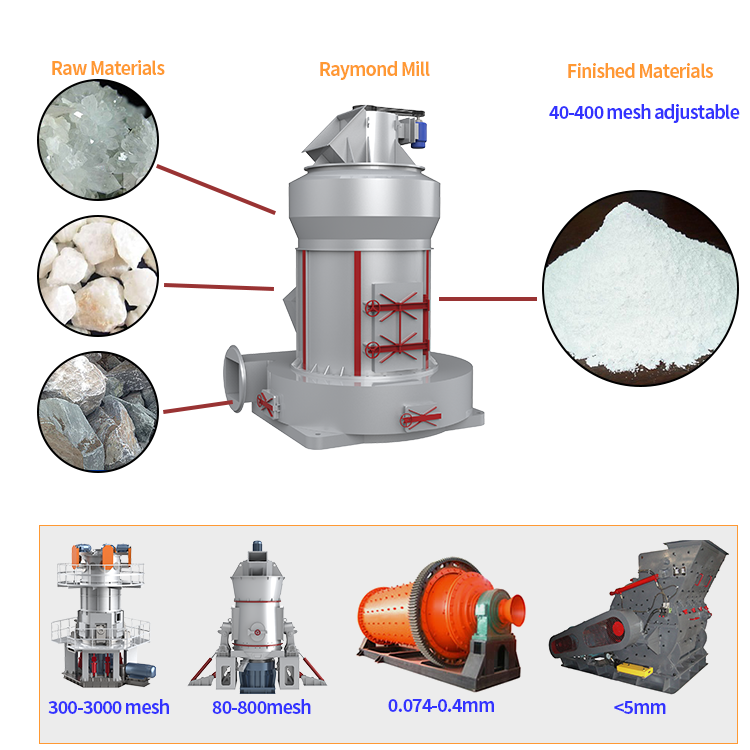

3. Raymond Grinding Machine (Equipment for the Connection of Grinding and Crushing)

The Cronus Raymond Mill is designed for grinding non-flammable and non-explosive ores, suitable for Zambian copper ores (Mohs hardness ≤7, moisture content <6%). It grinds finely crushed ore (≤30mm) to 80-600 mesh, with a 325-mesh throughput rate ≥95%, meeting the fineness requirements for subsequent flotation and magnetic separation. Its core advantages include 30%-40% higher energy efficiency than traditional ball mills, a vertical layout (occupying <50% space of ball mills) for space-constrained sites, alloy steel key components, low failure rate, and suitability for long-term continuous production via centrifugal extrusion and shearing of ore by grinding rollers and rings.

II. Core Adaptation Advantages

- Strong Adaptability: The material and structure of the equipment are specifically designed for high-hardness and low-humidity copper mines in Zambia. It is wear-resistant and durable, reducing the frequency of local spare parts procurement.

- Energy-saving and efficient: The core equipment such as the Raymond grinding machine reduces energy consumption by 30% - 40% compared to traditional equipment. This meets the energy-saving and cost-reduction requirements of the Zambian mines and helps lower operational costs.

- Easy operation and maintenance: The equipment has a simple structure and standardized maintenance procedures. No complex technologies are required. It is compatible with the local mine's operational capabilities and can also provide customized after-sales technical support.

- Flexible customization: Based on the production capacity (from small and medium-sized to large) of different mines in Zambia, as well as the site conditions and discharge requirements, we can provide a complete set of production line configuration solutions, taking into account both fixed production lines and flexible operation needs.

With its comprehensive crushing - screening - auxiliary equipment system, Cronus can provide an integrated solution for copper mining in Zambia, covering raw material processing to pre-treatment of beneficiation. It takes into account efficiency, cost and adaptability, helping local mines increase production capacity and economic benefits.