Desulfurized gypsum powder is a powder processed from desulfurized gypsum blocks. Manufacturers generally require an hourly processing capacity of around 10 tons. It typically appears as white or colorless crystals and plays a vital role in national economic development. It is widely used in a variety of fields, including construction, building materials, chemicals, food, molds, art models, and decoration.

In recent years, the applications of desulfurized gypsum powder have continued to expand, and its economic value has rapidly increased, attracting more investment. So, what equipment should be used to produce 10 tons of desulfurized gypsum powder per hour? Market research indicates that Cronus' desulfurized gypsum powder mill is an ideal choice, offering high quality, excellent performance, low price, and excellent service. Below is a detailed introduction. 10 tons per hour desulfurized gypsum powder processing equipment - Desulfurized gypsum grinding mill

High quality

Cronus continuously draws on innovative technologies from Germany, the United States, Japan, and other countries in the production of desulfurized gypsum grinding mills, maintaining a state-of-the-art approach. We also select high-quality, high-end, and durable domestic raw materials. We are meticulous and responsible in our workmanship, ensuring the production of high-quality equipment. Its lifespan is at least 3-5 times longer than that of grinding mills from other manufacturers. The equipment operates smoothly and reliably, reducing the failure rate by at least 60%.

Good performance

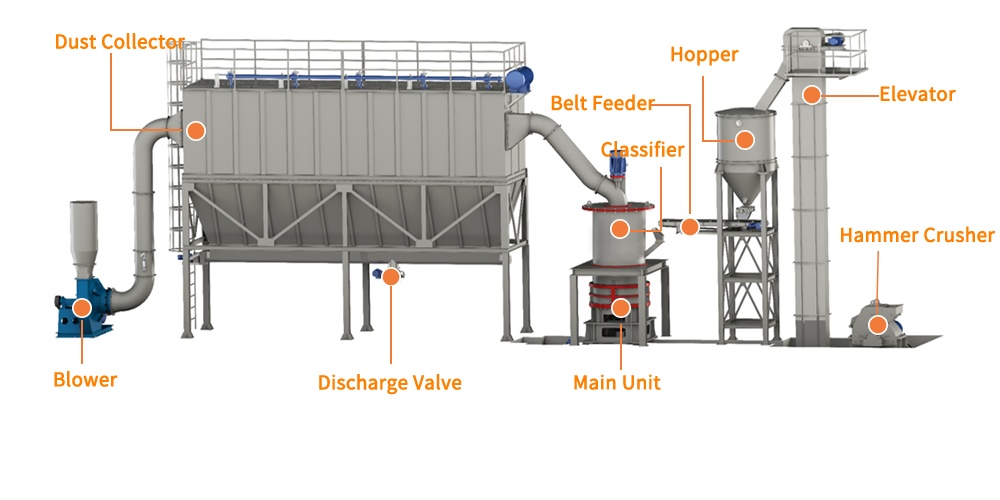

(1) Small size, strong system, small footprint, low investment, from raw material feeding to production processing, discharging and packaging, all links can form an independent production system;

(2) Good safety performance, designed with explosion-proof and dust-proof devices to avoid accidental explosion accidents, while reducing dust pollution to the environmental protection range;

(3) Computer automatic control, no workshop personnel required, quick installation and easy operation;

(4) High efficiency, large output, screening rate ≥99.99%, fine powder after grinding is of high quality and high economic value;

(5) Energy saving, power saving, stable, few failures, easy maintenance, annual operating expenses are reduced by at least 30,000 yuan.

Low price

The price of the desulfurization gypsum grinding mill designed by our company is very favorable. Compared with the equipment of the same quality and specifications, our company can offer a price discount of about 3%-7%. Therefore, it has won the trust of users and attracted the attention of many domestic and foreign users. It is a high-quality equipment with a high cost-effectiveness advantage in the industry. 4. Excellent Service

The manufacturer provides comprehensive after-sales service from a customer-centric perspective. With a dedicated attitude, we provide a comprehensive after-sales service package. From pre-purchase guidance and specification briefings to contract signing, on-site equipment tours and test drives, and finally, free on-site installation, repairs, and maintenance, all services are provided free of charge.

Cronus specializes in producing desulfurized gypsum powder processing equipment. It is one of the most reputable and reputable milling mill manufacturers in the industry, a leading company in Shanghai. Its mills are of high quality and offer a comprehensive range, making them highly trustworthy.