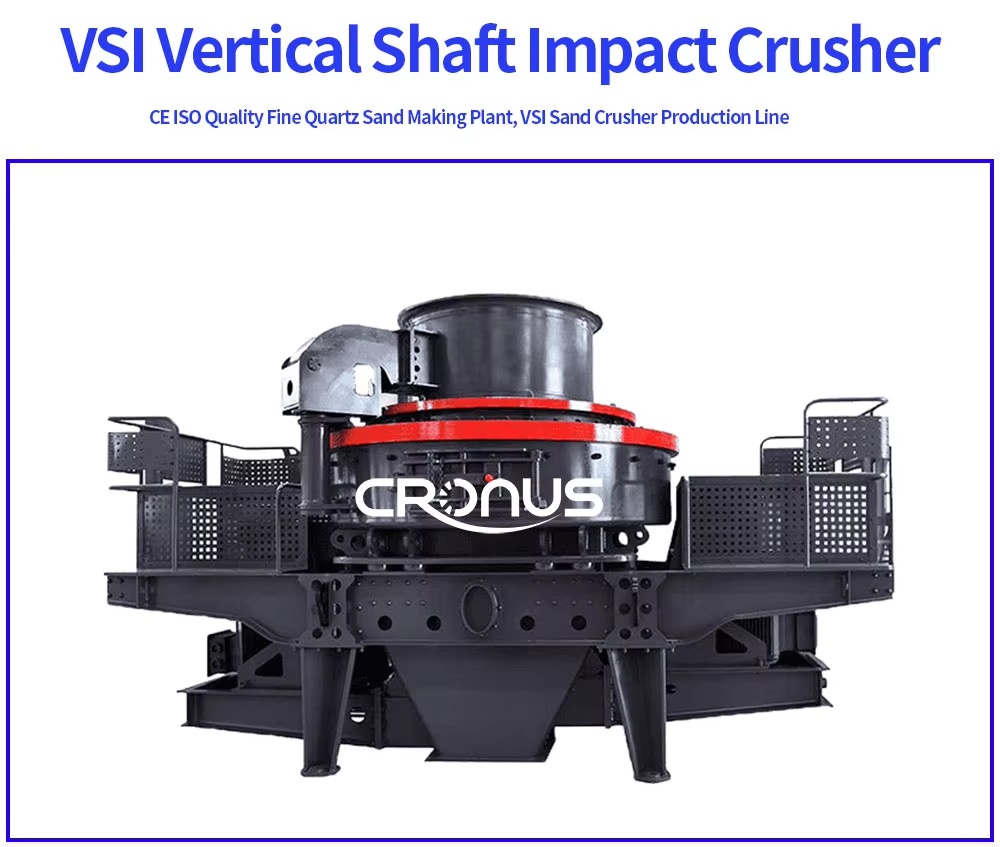

Sand and gravel are key raw materials for infrastructure. With manufactured sand inevitably replacing natural sand as an industry trend, infrastructure projects demand higher standards for sand quality. To meet the market's need for high-quality manufactured sand, Cronus integrates global advanced experiences, and through relentless R&D and tech innovation, has launched the internationally advanced Cronus VSI Vertical Shaft Impact Crusher—an elite sand-making and shaping solution. Since its market debut, the equipment has rapidly gained widespread user recognition, standing as the core equipment in the manufactured sand and stone shaping sectors.

The Cronus VSI series vertical shaft impact crusher is a high-performance energy-saving and material-saving crushing and shaping equipment with international advanced level, which is developed and produced by our company by introducing the latest European technology. It is widely applied in the medium and fine crushing fields of various high-hardness and extra-hard materials such as ores, cement, refractory materials, bauxite clinker, corundum, and glass raw materials. It is widely used in the crushing of mechanical construction sand, stone materials and various metallurgical slag. Especially for medium-hard and extra-hard materials, it has more advantages than other types of crushers, with high output and efficiency.

Cronus VSI Vertical Shaft Impact Crusher leverages high-speed material self-impact and inter-material friction grinding. By imparting sufficient kinetic energy to materials, it converts this energy into crushing force through impact, breaking materials along their natural texture and cleavage planes—delivering excellent particle shape and low wear. The equipment offers two feeding modes: "waterfall" and "center feed," enabling switching between "stone-on-stone" and "stone-on-iron" operating principles. It features four exclusive overflow ratio adjustment modes: "Stone-on-Stone", "Stone-on-Iron", "Stone-on-Stone → Stone-on-Stone", and "Stone-on-Stone → Stone-on-Iron". With a dedicated modular design, these four modes are interchangeable, adapting to diverse material flows and stone types.

Core technology: After the impeller adopts a brand-new four-port deep cavity design, the material acceleration flow line becomes more perfect and smooth, the material throughput increases by approximately 35%, and the production capacity is significantly enhanced, making it more energy-efficient and high-performance.

Reduce tonnage consumption: Optimize the design of wear parts, reduce their weight, make rotor dynamic balance easier, improve operational stability, and extend service life.

Excellent particle shape: It has two production modes, "stone-on-stone" and "stone-on-iron", which can meet the needs of different customers. The finished products have good particle shape, are multi-faceted cubes, and have a low content of needles and flakes. High efficiency and environmental protection: The equipment has high sealing performance. During the entire crushing process, the materials are crushed by mutual impact. The ingenious self-circulation of air flow inside the vortex chamber reduces dust pollution, making the production more efficient and environmentally friendly.

Simple operation and convenient maintenance: It adopts a dedicated hydraulic lid-opening device, which enables the upper cover to be moved quickly and conveniently, saving labor and effort for inspecting the internal components of the machine body.

Cronus focuses on the research and development and manufacturing of large-scale equipment required for infrastructure construction projects in mining, construction, energy and other fields, and provides professional solutions and mature supporting products. Enable sand and gravel customers to easily enjoy a safer, more environmentally friendly, more efficient and smarter overall solution and service for green circular building materials.