Gypsum is a critical non-metallic mineral material. Its abundant resources and excellent properties make it widely used in building materials, decoration, and industry. Whether it's gypsum board, moisture-proof gypsum board, gypsum mortar, putty, or self-leveling plaster, the production process requires fine grinding of gypsum. Raymond mills, as mature powder processing equipment, are core equipment in gypsum powder production lines due to their high efficiency, stability, and controllability.

Major Applications of Gypsum

Gypsum Board: Used for interior partitions and ceilings, it offers fire resistance, sound insulation, and lightweight properties.

Fiber-Reinforced Gypsum Board: Fiber-Reinforced for high-strength wall or decorative surfaces.

Moisture-Reinforced Gypsum Board: Water-Repellent, suitable for humid environments such as bathrooms and basements.

Gypsum Mortar and Putty

Plastering Gypsum: An alternative to cement mortar, offering fast application, crack resistance, and environmental protection and energy conservation.

Decorative Gypsum Molding: Used for decorative elements such as ceiling moldings and corner moldings.

Self-leveling gypsum: Used for floor leveling, it dries quickly and has low shrinkage.

Other building materials

Fire retardant coatings: Gypsum-based fire retardant coatings provide fire protection for steel structures.

Gypsum bricks/blocks: Lightweight partition materials, energy-saving and environmentally friendly.

The role of Raymond mills in gypsum processing

Gypsum requires calcination and grinding before use to achieve the fineness and activity requirements of different products. Raymond mills offer the following advantages in grinding:

High-efficiency grinding

The multi-stage grinding system allows for adjustable powder fineness, meeting various specifications from 80 to 325 mesh.

Stable product quality

Uniform powder particle size effectively improves the molding strength and surface finish of gypsum products.

Stable operation and easy maintenance

The proven and reliable structure allows for easy replacement of wearing parts, reducing downtime.

Energy saving and environmental protection

The sealed negative pressure system minimizes dust spillage and improves the production environment.

Typical Production Line Process

Raw Material Crushing: Natural gypsum is crushed to a particle size of less than 30mm.

Calcination: Water of crystallization is removed in the gypsum calcining equipment to produce gypsum.

Raymond Mill Grinding: Grinds the gypsum to the desired fineness.

Classification and Collection: Particle size is controlled using a classifier, and the finished product is collected through a collection system.

Packaging and Storage: Moisture-proof sealing ensures consistent quality during transportation and use.

Conclusion

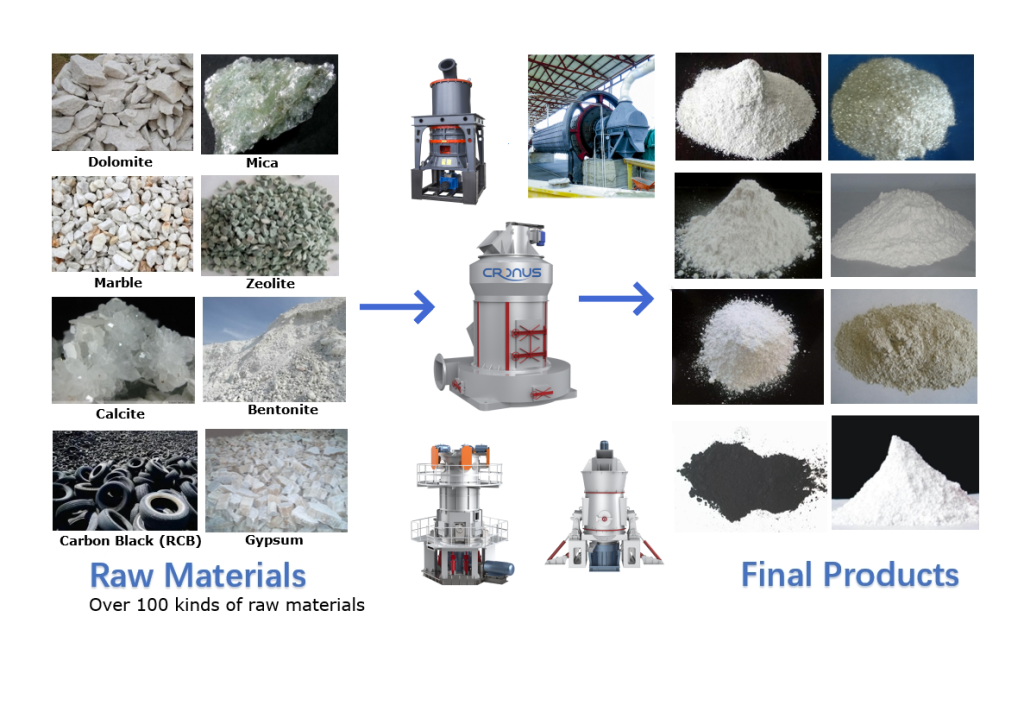

The Raymond Mill is not only the core equipment for gypsum powder processing, but also a crucial factor in ensuring the quality and production efficiency of gypsum products. Cronus provides customers with a one-stop solution from raw material crushing, calcination, grinding, classification, and packaging to meet the diverse production needs of building gypsum, decorative gypsum, and industrial gypsum.

Contact us to discuss the gypsum grinding equipment solution tailored to your project, making your gypsum processing line more efficient, environmentally friendly, and competitive.