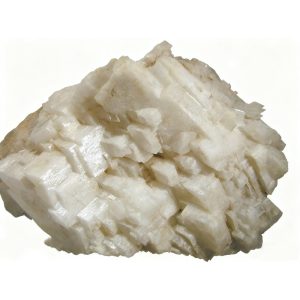

Feldspar is the most important rock-forming mineral in surface rocks. Feldspar is the general term for feldspar minerals. It is a common type of aluminosilicate rock-forming mineral containing calcium, sodium and potassium.

Feldspar rich in potassium or sodium is mainly used in the ceramic industry, glass industry and enamel industry. Feldspar containing rare elements such as rubidium and cesium can be used as mineral raw materials for extracting these elements. Feldspar with beautiful color can be used as decorative stone and inferior gemstones.

| Property | Value Range |

|---|---|

| Mohs Scale | 6 - 6.5 |

| Specific Gravity | 2.55 - 2.75 |

The feldspar crushing production line is a high-yield and low-consumption feldspar crushing production line with a designed output of 250 tons per hour. The operation effect of this production line so far shows that among the local feldspar production lines, its cost is very low and the operation effect is also very good. It has become a representative production line that other producers are eager to follow.

Equipment configuration

jaw crusher

cylinder hydraulic cone crusher

European version hydraulic three-chamber impact crusher

Process flow

The feldspar raw material enters the deep chamber jaw crusher for rough crushing, and then goes into the multi-cylinder hydraulic cone crusher for secondary crushing. The material coming out of the multi-cylinder hydraulic cone crusher enters the European version of the three-chamber pressure impact crusher for crushing. This production line has a high yield rate and is currently the most widely recognized feldspar crushing production line in the local area for its product quality while having a very low production cost.

Advantages of equipment configuration

The multi-cylinder hydraulic cone crusher has a high rotational speed, adopts the principle of layering crushing, has a large output, low energy consumption, significantly reduces production costs, and increases profits. Moreover, the multi-cylinder hydraulic cone crusher adopts full thin oil lubrication, which greatly extends the service life of the equipment. Workers do not need to apply grease every shift, saving the maintenance and repair time of the equipment. The multi-cylinder hydraulic cone crusher adopts hydraulic protection and hydraulic cavity cleaning, featuring a high degree of automation, simpler maintenance, more convenient operation, reduced downtime, increased production time of the equipment, and enhanced output.

The impact crusher is equipped with a hydraulic lifting device, making the maintenance of the equipment and the replacement of vulnerable parts convenient and fast. The heavy-duty rotor design enables the rotor to achieve a greater moment of inertia during rotation, enhances the impact force and increases the output.

The impact crusher adopts the European version of the three-chamber impact crusher. Compared with the traditional two-chamber impact crusher, the three-chamber impact crusher has the material in the chamber, with more impact times, a higher one-time forming rate, and more fine materials, which just meets the requirements of feldspar crushing.

Customer site

The outstanding performance of the feldspar crushing production line fully demonstrates Cronus' technical strength and solution design capabilities in the field of mining equipment. By precisely configuring highly efficient and energy-saving deep chamber jaw crushers, multi-cylinder hydraulic cone crushers and European three-chamber impact crushers, this production line has achieved a high output target of 250 tons per hour while significantly reducing operating costs and maintenance intensity, becoming a benchmark case for quality improvement and efficiency enhancement in the feldspar processing industry. Cronus will continue to be supported by innovative technologies, reliable equipment and refined services to help more customers build modern production lines that are low-consumption, high-yield and sustainable in profit, and jointly create new value for the industry.