Maximize operational performance with advanced lime slaker equipment designed to deliver efficient, safe, and cost-effective lime hydration. Our systems are ideal for applications in municipal water treatment, flue gas desulfurization (FGD), industrial wastewater processing, and more.

What is Lime Slaker Equipment?

Lime slaker equipment, also called a lime hydrator, is a specialized system that converts quicklime (CaO) into slaked lime (Ca(OH)₂) through a precisely controlled hydration process. This exothermic reaction plays a vital role in water treatment and chemical applications, where consistent lime slurry output is critical.

Chemical Reaction:

CaO + H₂O → Ca(OH)₂ + Heat

Properly designed lime slakers help reduce operating costs, improve process stability, and prevent lime wastage.

Common Applications of Lime Slakers

Our lime slaking equipment is widely used in the following industries:

🏭 Municipal water treatment – For water softening and pH regulation

⚡ Power plants – In FGD systems for SO₂ capture

🧪 Chemical processing – As a reagent in various reaction chains

⛏ Mining & metallurgy – For neutralizing acidic effluents

How Our Lime Slaker Equipment Works

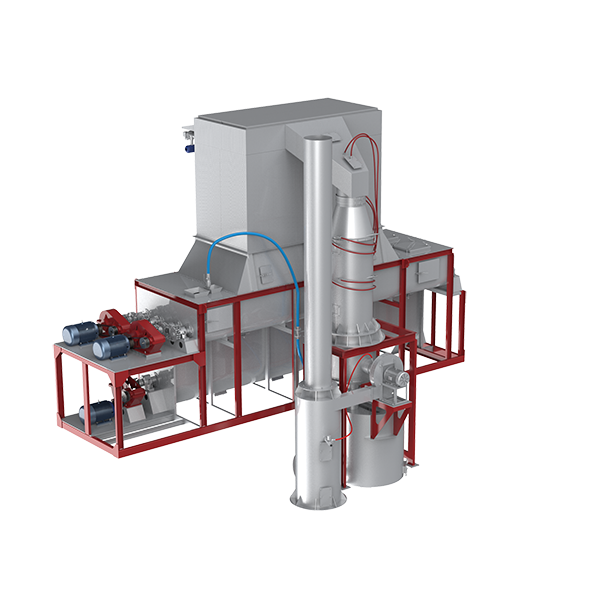

Our lime slaking system integrates advanced automation and robust components to ensure reliable performance:

Key Components:Quicklime feeding system: Automatically dispenses precise lime quantities

Slaking tank: Reacts lime with water to generate slaked lime slurry

Agitator / mixer: Ensures homogeneous slurry and even heat distribution

Control panel (PLC): Adjusts slaking parameters in real-time

After slaking, the lime slurry is pumped to storage or directly to dosing systems used in water or gas treatment lines.

Key Features of Our Lime Slaking Systems

As referenced in industry-leading designs, our lime slaker equipment offers the following benefits:

✔ High Efficiency

Full hydration with minimal unreacted lime, reducing product waste.

✔ Durable Materials

Tanks and frames are built with stainless steel or anti-corrosive carbon steel for long service life.

✔ Automated Control

Fully integrated PLC systems allow remote monitoring and automatic operation.

✔ Modular & Scalable

Available in various sizes and configurations to meet small or large-scale project demands.

✔ Low Maintenance

User-friendly design with easy access to all mechanical parts for cleaning and servicing.

Why Choose Our Lime Slaker Equipment?

Choosing the right lime slaker system is key to ensuring safe operations, environmental compliance, and cost savings. We provide:

✅ Customized engineering solutions based on your site conditions

✅ Turnkey service, including installation, commissioning, and training

✅ More than 30+ industries served, with proven performance in harsh environments

✅ Energy-efficient design that reduces operational cost per ton of lime

Contact Us for Lime Slaker Solutions

Looking to upgrade or install a high-efficiency lime slaker system? Contact our technical team today to explore tailored solutions for your water treatment or industrial needs.