Shanghai Cronus has been deeply engaged in the research and manufacturing of industrial grinding equipment. It has developed four core series of powder grinding machines: Raymond mill, vertical mill, ultrafine mill, and ring roller mill. These machines are specifically designed for multiple materials such as calcined coke, carbon black, limestone, and kaolin, and are tailored to meet the processing requirements of fine particle sizes ranging from 80 to 2500 mesh. They are suitable for processing non-flammable and non-explosive materials with a Mohs hardness of less than 7 and a moisture content of 0-12%.

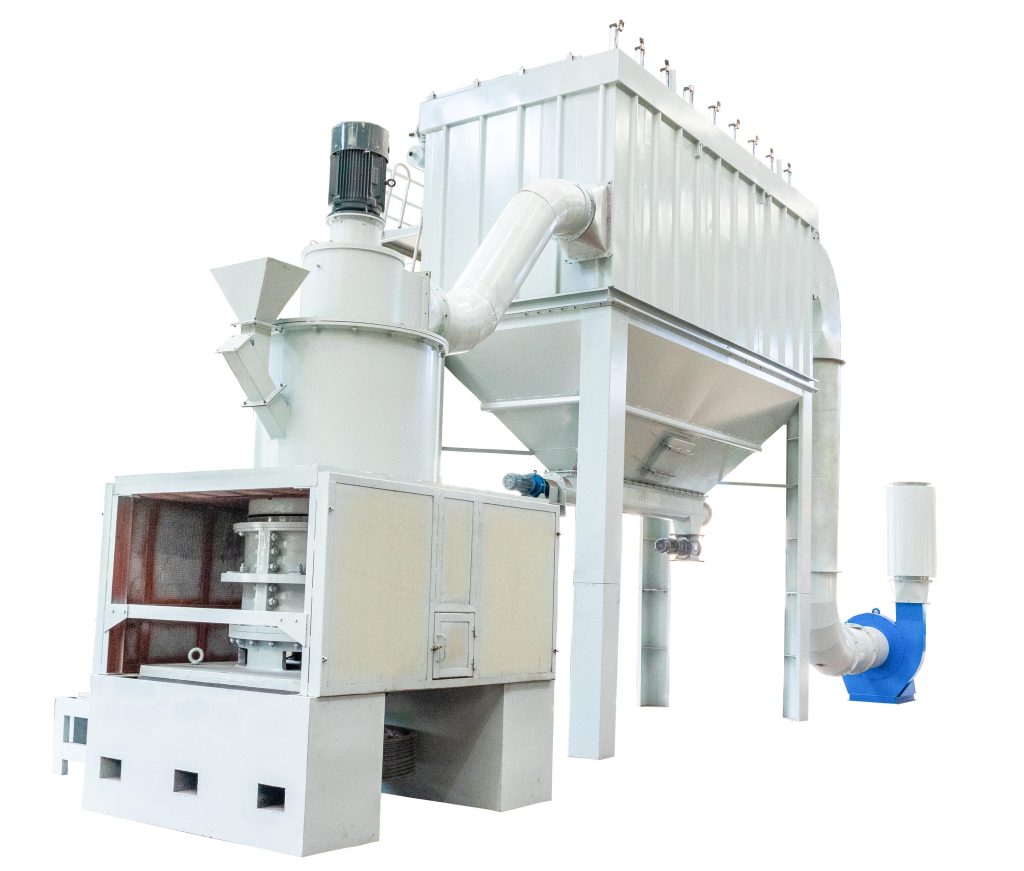

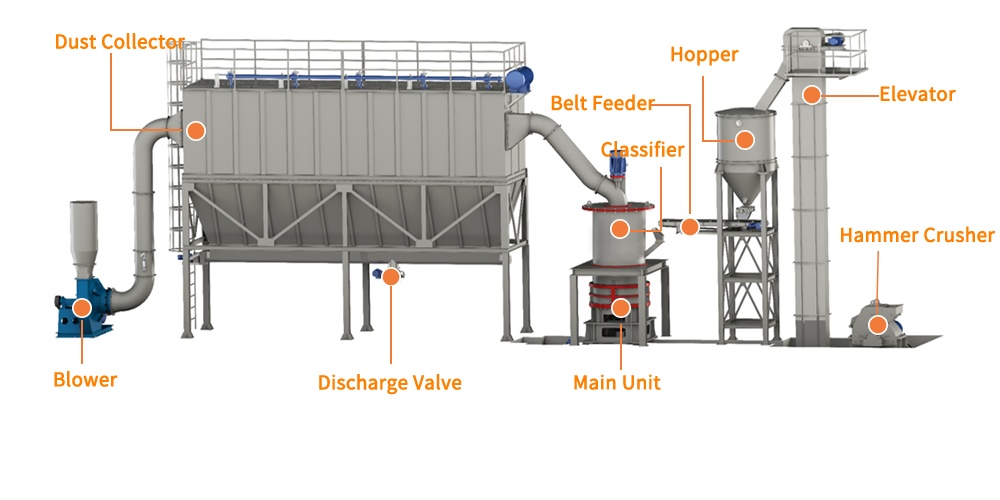

Raymond Mill

Fineness: 80 - 325 mesh

Capacity: 1 - 80 t/h

Application: The equipment is applicable to industries such as building materials, metallurgy, power, chemical industry, transportation, mining, etc. It can grind various non-flammable and non-explosive materials with a Mohs hardness of less than 7, including talc, barite, calcite, limestone, manganese ore, iron ore soil, chromium ore, quartz stone, gypsum, bentonite, etc.

The CRRM Raymond Grinding Mill is a patented technology product that has been continuously developed and improved by Klonos after the introduction of the design drawings. It consists of the main machine, classifier, blower, piping system, pulse dust collector, electrical control system, as well as the crusher, feeder, and elevator, and other supporting equipment. It is one of the main equipment for processing non-metallic mineral powders.

The equipment is widely used in the industries such as building materials, metallurgy, power, chemical engineering, transportation, and mining for the grinding processing of mineral products and materials. It includes calcium carbonate grinding, gypsum powder, power plant desulfurization, non-metallic mineral grinding, coal powder preparation, etc. It is applicable to various non-flammable and non-explosive materials with a Mohs hardness of less than 7 and a humidity of less than 6%.

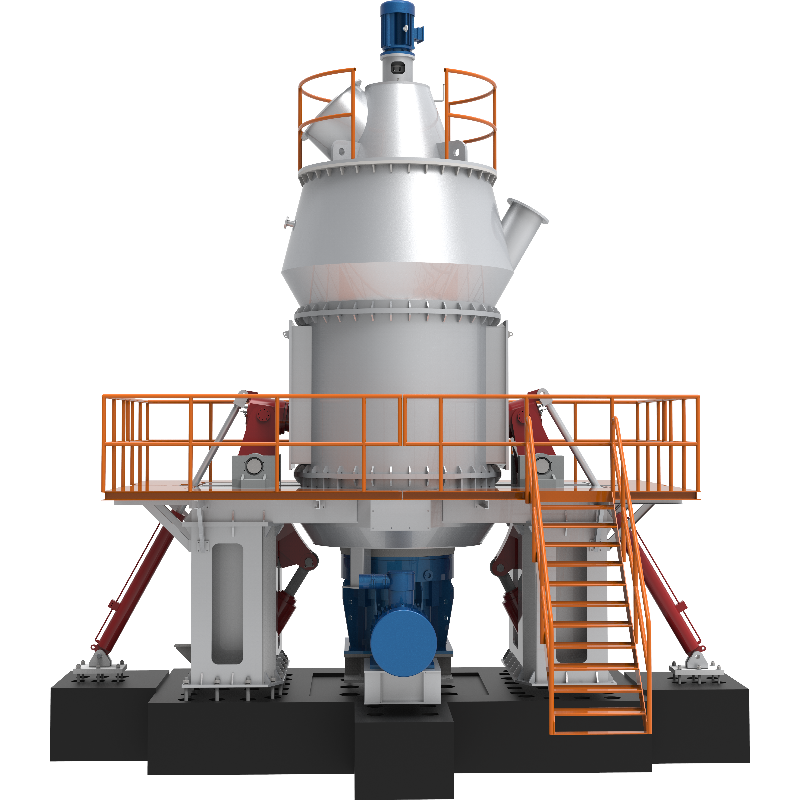

Vertical Mill

- Fineness: 80 - 600 mesh

- Capacity: 25 - 34 t/h

- Application: The equipment is applicable to industries such as cement, metallurgy, chemical engineering, solid waste treatment, non-metallic materials, non-ferrous metals, power plant coal grinding, etc. It is used for grinding materials such as cement raw materials, clinker (slag), coal, gypsum, talc, calcite, quartz, zinc, tin, etc.

Ultrafine Mill

Capacity: 3.8 - 16 tons per hour

Fineness: 325 - 1500 mesh

Particle size distribution D97: 10 - 45 ± 1

Specific surface area: ±1000 cm²/g

Production capacity: 3.8 - 16 t/h; It can provide high-quality fillers and additives for industries such as papermaking, plastics, coatings, rubber, ink, and chemicals.

Ring Roller Mill

Fineness: 800 - 2500 mesh

Capacity: 0.6 - 2.8 t/h

Application: Suitable for crushing brittle materials with hardness less than 6 grades, such as heavy calcium (calcite, marble, dolomite, etc.), barite, talc gypsum, petroleum coke, white carbon black, magnesite, hydrogenaluminum hydride, white powder, wollastonite, kaolin, bentonite, rare earth, etc.