In recent years, the market demand for powder grinding machines in Malaysia has continued to grow, especially in the fields of mineral processing, building materials and chemicals. As an efficient and reliable grinding equipment, Raymond mill has become one of the mainstream choices in this market due to its excellent performance and wide range of applications.

Overview of the Malaysian Powder Grinding Machine Market

In Malaysia, powder grinding machines are mainly used to process various non-flammable and non-explosive materials, such as calcite, limestone, dolomite, etc. After grinding, these materials can be widely used in building materials, chemical raw materials, food additives and other fields.

| Property | Value |

|---|---|

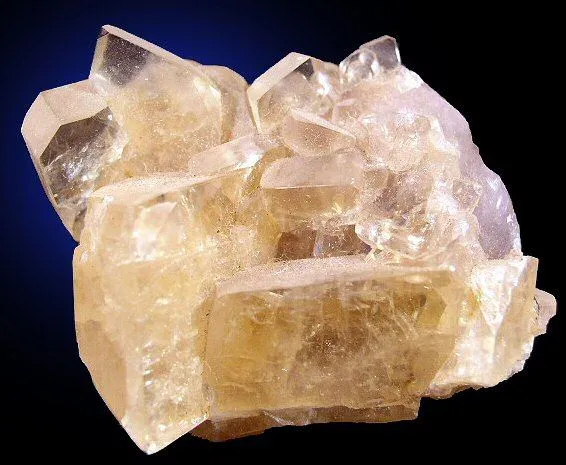

| Name | Barite |

| Mohs Hardness | 3 - 3.5 |

| Specific Gravity | 4.0 - 4.6 |

| Crystal Type | Orthorhombic |

| Category | Sulfate mineral |

For example, Barite is one of the important processing objects of grinding machines due to its high density and chemical inertness. In addition, with the advancement of technology, the fine powder particle size of the grinding machine has gradually increased, meeting the market demand for ultrafine powder

Advantages of Cronus Raymond Mill

As a company focusing on the research and development and manufacturing of mining equipment, Cronus' Raymond Mill enjoys a high reputation in the Malaysian market. The following are the main features and advantages of Cronus Raymond Mill:

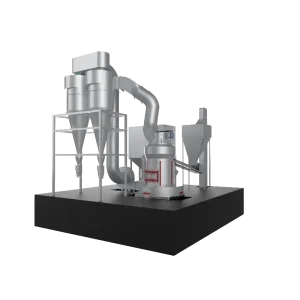

High efficiency and energy saving

The Cronus Raymond mill adopts advanced design, with high screening efficiency and low energy consumption. Its main shaft drive system adopts closed gear and belt drive, which runs smoothly and reliably, and has a high degree of automation, reducing manual operation.

Wide range of applications

The equipment is suitable for processing a variety of non-flammable and non-explosive materials, including brittle materials with hardness less than 7 and humidity less than 6% such as calcite, limestone, dolomite, bauxite, etc. In addition, it can also process minerals with lower hardness such as gypsum, quartz, etc.

Compact structure and easy maintenance

The Raymond mill has a compact structure design, small footprint, and easy replacement and maintenance of various components. Its grinding roller and grinding ring have a long service life, reducing long-term operating costs.

Adjustable finished product particle size

By adjusting the wind speed and pressure inside the equipment, users can flexibly control the particle size range of the finished fine powder, from 325 mesh to 400 mesh or even higher.

Wide range of applications

Raymond mills are not only suitable for the building materials industry, but also for chemical, metallurgical, environmental protection and other fields. For example, in Malaysia, Cronus's Raymond mills are widely used in fine powder processing in gypsum mines, limestone mines and other mines.

Cronus's performance in the Malaysian market

Cronus has won a good reputation in the Malaysian market with its excellent product quality and professional technical support. The Raymond mill provided by Cronus not only meets the local customers' demand for efficient and environmentally friendly equipment, but also ensures the stable operation and long-term benefits of the equipment through a complete after-sales service system.

The Malaysian powder grinding machine market has an increasing demand for efficient and energy-saving equipment. Cronus's Raymond mill occupies an important position in this market with its high efficiency and energy saving, wide range of applications and compact structure. If you are looking for a high-performance and reliable grinding equipment, Cronus's Raymond mill will be your ideal choice.

For more product information or technical consultation, please contact Cronus.