The development and expansion of the construction industry has boosted the demand and consumption of pyrophyllite. In ceramic manufacturing, pyrophyllite can improve mechanical strength and whiteness at low temperatures. Because pyrophyllite remains stable at temperatures up to 800°C, it is highly regarded in refractory materials and products such as wall tiles, sanitary ware and electrical porcelain, and also plays a key role in the development of the ceramic industry.

Application of pyrophyllite

| Property | Value or Description |

|---|---|

| Name | Pyrophyllite |

| Category | Silicate |

| Hardness | 1-2 |

| Density | 2.65-2.90 g/cm³ |

| Applications | Refractory materials, ceramics, electric porcelain, crucibles, glass fiber |

Refractory materials

Amorphous refractory materials:

pyrophyllite can produce volume expansion, improve material properties and extend service life. For example, kaolin containing pyrophyllite phase can improve the plasticity and sintering strength of cannon mud. Pyrophyllite plays an important role in the volume stability of various amorphous refractory materials.

Shaped refractory materials:

adding to refractory bricks can improve volume stability. After the micro-expansion high-alumina bricks are introduced with pyrophyllite, the slag erosion resistance is enhanced; clay-pyrophyllite bricks can replace expensive cylinder bricks for coke oven cooling platforms, and the service life exceeds 7 years.

Ceramic field

Architectural sanitary ceramics: It is a high-quality raw material that can achieve rapid firing, small product shrinkage, high strength, and can also reduce costs. It is used to make various types of ceramics and daily ceramics.

Acid-resistant ceramics:

It can improve the chemical stability of ceramics.

Dielectric ceramics:

After purification, the dielectric properties can be improved.

Ceramic abrasives:

It can improve performance, prevent the black heart phenomenon of silicon carbide abrasives, and widen the sintering temperature range.

Advantages of Raymond mill for processing pyrophyllite

Pyrophyllite has a low Mohs hardness and a soft texture. It is easily crushed in the Raymond mill, which reduces equipment wear and extends service life. The Raymond mill adopts a scientific crushing principle. The grinding roller presses the grinding ring under the action of centrifugal force, rotates and crushes the pyrophyllite, and the scraper evenly distributes the material to ensure full grinding. The classifier accurately separates fine powder from coarse powder, collects fine powder, and re-grinds coarse powder, effectively improving grinding efficiency and product quality stability. The Raymond mill has flexible fineness adjustment and can easily grind pyrophyllite powder to 80-400 mesh.

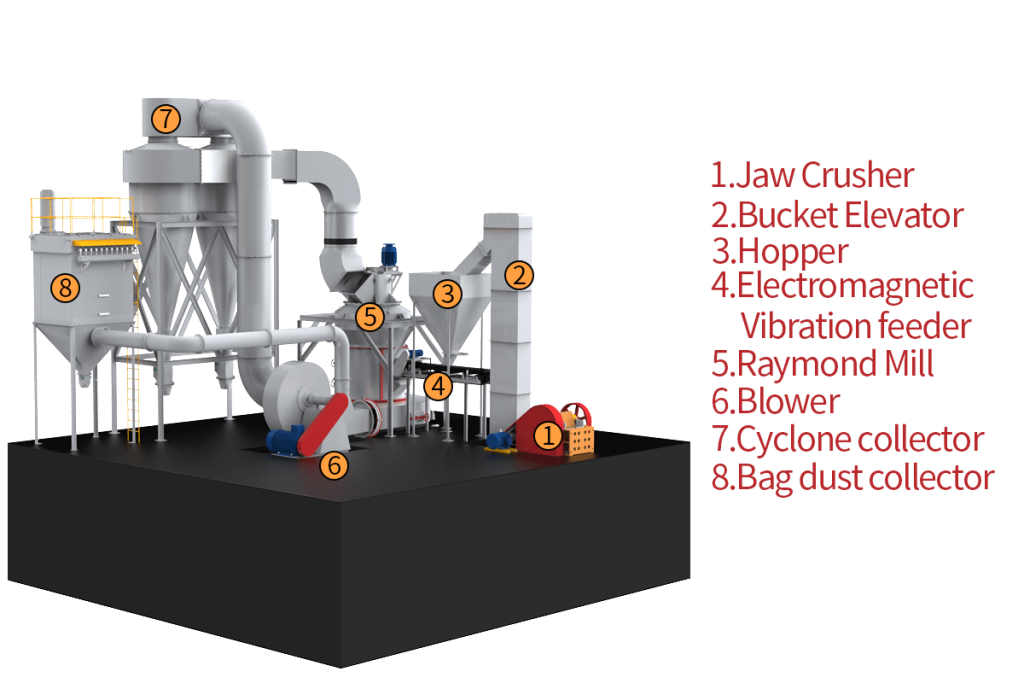

A complete explanation of the process of processing pyrophyllite with Raymond mill

Crushing stage: The jaw crusher coarsely crushes the pyrophyllite to particles ≤30mm to meet the feeding requirements of the Raymond mill.

Grinding core: In the Raymond mill, the grinding roller and grinding ring rotate at high speed to grind the pyrophyllite efficiently. Usually 1-3 cycles can achieve the required fineness, and the scraper ensures that the material is fully ground.

Classification and screening: The classifier accurately separates the powder particle size, and the qualified fine powder enters the cyclone collector, and the coarse powder returns to the grinding area for re-grinding to ensure that the finished product particle size is uniform and stable.

Finished product collection: The cyclone collector separates the powder and the airflow, and the pulse dust collector further purifies it to ensure the purity of the finished powder, and finally it is packaged or transported to the downstream process.

Cronus grinding machines are characterized by excellent performance and reliable quality, precise powder control, energy-saving and high efficiency, durability and peace of mind. We not only provide high-quality equipment, but also have a professional after-sales team to escort you throughout the process. If you need a grinding machine, please contact Cronus and start a new experience of intelligent grinding!