Pyrophyllite ore has attracted attention due to its unique properties and broad range of applications. Pyrophyllite is a soft mineral primarily composed of aluminosilicate, widely used in the production of ceramics, refractory materials, coatings, plastics, and other products. With the growing global demand, the pyrophyllite ore market has become a focal point for investors, manufacturers, and environmental experts.

Global Demand for Pyrophyllite Ore

Over the past decade, the pyrophyllite ore market has shown steady growth. The demand is mainly driven by its applications in high-temperature environments, particularly in the production of refractory materials and ceramics. The ceramic industry, especially in Asia, remains the largest consumer of pyrophyllite, which is used in the production of tiles, sanitary ceramics, and other durable products.

Additionally, with the increasing demand for eco-friendly and sustainable materials, pyrophyllite's use in various green technologies has also risen. Its low environmental impact during mining and processing makes it a strong alternative to other industrial minerals.

Key Applications of Pyrophyllite Ore

- Ceramics and Pottery: Pyrophyllite is used as a flux in ceramics production because it lowers the melting point of raw materials. This makes it crucial in producing durable products like pottery, tiles, and sanitary ceramics.

- Refractory Materials: Pyrophyllite has high heat resistance and a low thermal expansion coefficient, making it important in the production of refractory materials, especially in industries such as steel, cement, and glass manufacturing.

- Coatings and Paints: Pyrophyllite is used as a filler in coatings and paints, providing a smooth surface and improving durability.

- Plastics: As a filler in plastics, pyrophyllite enhances material strength, thermal stability, and heat resistance.

- Other Uses: Pyrophyllite is also used in the production of cosmetics, rubber, and electrical insulation materials. As research progresses, its new applications continue to be discovered.

Advantages of Raymond Mill for Processing Pyrophyllite Ore

For the processing of pyrophyllite ore, Raymond mills provide an efficient and cost-effective solution. This mill is particularly suitable for processing pyrophyllite ore, enabling stable and efficient large-scale production.

Key Features of the Raymond Mill:

- Grinding Rollers: The grinding rollers in the Raymond mill play a central role in the grinding process, allowing for adjustment of fineness and improving efficiency. The rollers grind the material into powder by rotating and applying pressure, ensuring uniform particle size. Made from high-hardness, wear-resistant materials, they have a long service life, improving equipment stability and durability.

- Grinding Ring: The grinding ring and rollers work together at high speeds to grind large materials into fine powder. The grinding ring’s core function is to support the rollers and help them roll along a stable trajectory, ensuring efficient operation.

- Shovel: The shovel lifts the material entering the mill and delivers it to the area between the rollers and the grinding ring for further grinding. It is usually made of wear-resistant materials to resist wear.

- Classifier: The classifier is used to control the fineness of the finished product by adjusting its speed to regulate the powder particle size.

- Fan: The fan blows the ground powder into the classifier for sorting, ensuring grading accuracy.

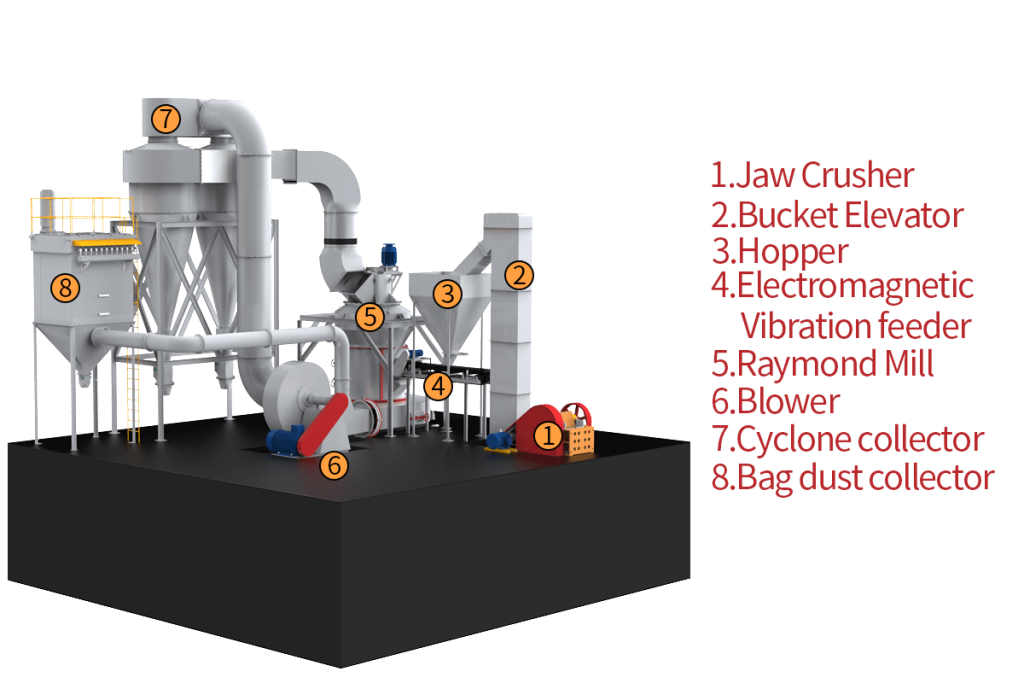

- Cyclone Collector: The cyclone collector is used to collect qualified finished powder, ensuring minimal dust leakage during the production process.

- Piping System: The piping system connects all parts of the equipment, ensuring smooth airflow and guaranteeing the stability and efficiency of the production process.

Working Principle of the Raymond Mill

- Pre-crushing: Large raw materials are crushed by a crusher to a size of ≤30mm for subsequent grinding.

- Quantitative Feeding: The electromagnetic vibrating feeder continuously and quantitatively feeds the crushed raw materials into the grinding zone, ensuring stable and continuous grinding.

- Grinding and Crushing: The grinding rollers, under centrifugal force, press on the rotating grinding ring to form a “crushing zone” where the material undergoes double extrusion and shear, resulting in powder.

- Classification and Sorting: The powder flows with the air into the turbine classifier. Coarse particles fall back into the grinding zone, while qualified fine powder enters the collection system. The classifier's speed controls the finished product's fineness.

- Efficient Collection: Qualified fine powder is separated and collected by the cyclone collector, ready for packaging or the next process.

Features of the Raymond Mill

- Capacity: 15~80t/h

- Fineness: 80~325 mesh

- Maximum Feed Size: 35mm

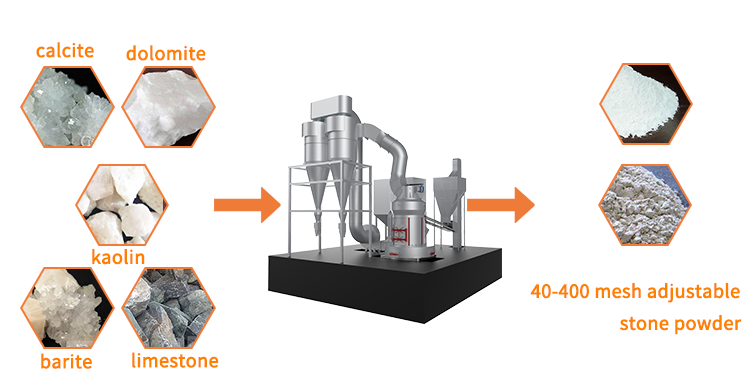

The Raymond mill is highly efficient in processing minerals with a Mohs hardness of seven or below and a humidity of less than 6%, such as limestone, marble, calcite, potassium feldspar, barite, dolomite, granite, pyrophyllite, kaolin, bauxite, gypsum, talc, fluorite, coal slag, red iron oxide, and iron ore. It allows flexible adjustment of the finished particle size, ranging from 80 to 325 mesh, with a maximum feed size of 35mm and a 325-mesh pass rate of ≥95%, ensuring uniform particle size. The production capacity ranges from 15 to 80 tons per hour.

Raymond mill parameter comparison table

| Model | Max Feed Size (mm) | Finished Product Size (mm) | Dimensions (L*W*H)(mm) (Without Dust Collector) |

Capacity (t/h) | Power (kW) | ||

|---|---|---|---|---|---|---|---|

| Main Unit | Fan | Classifier | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 | 45 | 15 |

| CRRM1280 | 20 | - | 8400×5650×8200 | 1.5~10 | 55 | 55 | 15 |

| 5R4128 | 20 | - | 8660×6050×9250 | 2~15 | 90 | 90 | 22 |

| CRRM1500 | 20 | - | 8700×5500×9250 | 3~18 | 110 | 110 | 22 |

| CRRM1620A | 30 | - | 9670×5570×10550 | 5~22 | 160 | 132 | 30 |

| CRRM1700 | 30 | - | 9670×5570×10550 | 6~28 | 185 | 160 | 37 |

| CRRM1850 | 30 | - | 10455×6830×9815 | 6.5~30 | 200 | 200 | 37 |

| CRRM1920 | 30 | - | 13312×7690×9815 | 7.5~33 | 220 | 220 | 45 |

| CRRM2150 | 30 | - | 11080×7600×11150 | 10~40 | 250 | 280 | 45 |

| CRRM2500 | 35 | - | 11480×7730×11250 | 11.5~50 | 280 | 280 | 45 |

| CRRM2750 | 35 | - | 17000×11000×15000 | 15~80 | 450 | 450 | 75 |

* The above data is for reference only. Please refer to the actual product or product manual for specific information.

The pyrophyllite ore market demonstrates strong growth potential due to its wide applications in ceramics, refractory materials, plastics, and other industries. Despite challenges such as supply constraints, price volatility, and environmental regulations, increasing demand for eco-friendly products and technological advancements present significant opportunities.

With rising global demand, pyrophyllite holds immense potential in green products and innovative applications. By adapting to market trends and overcoming challenges, companies in the pyrophyllite ore industry can secure a competitive position in the evolving global economy. As an efficient, energy-saving, and intelligent grinding solution, Raymond mills provide essential technical support for pyrophyllite ore processing, helping producers enhance productivity and product quality.