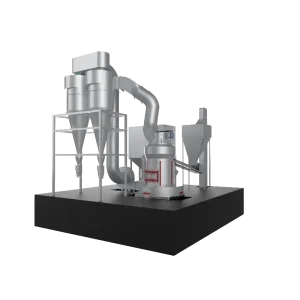

Raymond mill and magnesium oxide

Magnesium oxide is a widely used inorganic compound. In the field of refractory materials, it is the core raw material for manufacturing refractory bricks and refractory coatings, providing protection for high-temperature industrial equipment. In the pharmaceutical industry, as an antacid and laxative, it alleviates the problem of excessive stomach acid. In the field of environmental protection, it can handle industrial wastewater and waste gas, contributing to environmental protection. In industries such as electronics, rubber, and plastics, it can enhance product performance and expand application scope. The Raymond mill can grind magnesium oxide into powder of different fineness, meeting the demands of various industries.

The process of processing magnesium oxide by Raymond mill

Raw material pretreatment:

When processing magnesium oxide, raw material pretreatment is of vital importance to the grinding efficiency, quality and equipment operation. A moisture content of raw materials exceeding 6% can cause problems, such as damp materials adhering to the grinding rollers, reducing grinding efficiency, and possibly clogging the analyzer. Therefore, a rotary dryer is needed for drying. Large raw materials need to be pre-crushed into particles of ≤30mm by a jaw crusher to enhance grinding efficiency and reduce equipment wear and tear.

Grinding process

The pre-treated magnesium oxide material then moves to the grinding phase. During feeding, an electromagnetic vibrating feeder is employed to ensure a consistent and steady supply of material. It is important to avoid fluctuations in feed rate, whether too rapid or too slow, as this may affect process stability. Grinding forms the core of the process, where the grinding rollers, driven by centrifugal force, exert strong pressure against the grinding ring. The material is pulverized into fine powder under this intense compressive force. The efficiency of grinding depends on several factors, including the clearance between the grinding roller and the ring, the pressure applied by the rollers, and the physical characteristics of the material.

For classification, an analyzer is used to carry out precision separation. The rotation speed of the analyzer is critical, as it directly determines the fineness of the final product. In the collection stage, cyclone collectors and pulse-jet dust collectors work together to recover the qualified fine powder. This also ensures that emissions meet environmental standards before the exhaust gas is released.

Finished product packaging

After being processed into fine powder, magnesium oxide needs to be sealed and packaged to prevent moisture absorption. Use packaging materials with good moisture-proof performance, such as plastic film bags and composite paper bags, to ensure the stability of product quality.

Common problems in processing magnesium oxide with Raymond mill

Material adhesion or blockage

Magnesium oxide becomes more viscous after absorbing moisture, and it is prone to adhere to the grinding rollers and grinding rings, reducing grinding efficiency, accelerating wear and shortening the service life of equipment. Materials may also get clogged at the pipes and the analyzer, hindering material transportation and classification. Excessive moisture in the feed can also exacerbate this issue. The evaporation of water forms water vapor, making the material more humid and increasing its viscosity.

Solution:

Strictly control the moisture content of raw materials to be ≤6%, strengthen the monitoring of the drying process, and add drying equipment or extend the drying time when necessary. Install anti-sticking coatings, such as polyurethane coatings, on the inner walls of the mill to reduce material adhesion. Regularly clean the grinding rollers and pipelines, thoroughly remove adhering materials with professional tools, and inspect the equipment components.

Finished product fineness does not meet the standard

Unreasonable rotational speed of the analyzer is a common cause. If the rotational speed is too low, the fineness will be too coarse; if it is too high, it will increase energy consumption and costs. The wear of the grinding roller can also affect the fineness. Long-term grinding causes the surface of the grinding roller to no longer be smooth, and the crushing effect decreases.

Solution:

According to the fineness requirements of the product, adjust the rotational speed of the analyzer reasonably and find the most suitable rotational speed through experiments. Regularly inspect the wear condition of the grinding rollers, replace the worn grinding rollers and grinding rings in a timely manner, and select products with reliable quality and strong wear resistance.

Output decline

Air duct blockage is an important cause. The accumulation of materials in the pipeline hinders the flow of air and reduces the working efficiency of the mill. Insufficient pressure of the grinding roller will also reduce the output, and the material cannot be ground fully, requiring repeated grinding. Uneven feeding also leads to a decrease in output. In some areas, there is either too much or too little material, which affects the normal operation of the equipment.

Solution:

Regularly clean the accumulated powder on the fan and in the pipeline to ensure the unobstructed air duct. Check the hydraulic system to ensure the stability of the grinding roller pressure. The frequency of the feeder can be adjusted to maintain uniform feeding, and precise control can be achieved by installing an automatic control system.

Precautions for processing magnesium oxide with Raymond mill

Explosion-proof measures: Although magnesium oxide is not flammable, when processed into fine dust and reaching a certain concentration in the air, it may cause an explosion upon encountering a fire source. For this reason, grounding the equipment is a fundamental measure, which can conduct static electricity into the ground and eliminate the risk of explosion.

Dust removal system: Processing magnesium oxide generates a large amount of dust, and it is necessary to be equipped with a high-efficiency bag filter, such as a pulse filter. Dust is filtered through filter bags and automatically cleaned by the pulse jet system. The environmental protection department stipulates that the emission concentration should be ≤30mg/m³. Pulse dust collectors can easily meet the standards and protect the environment.

Operation protection: Operators are at risk of inhaling MgO dust. Long-term exposure can damage the respiratory tract and cause serious diseases such as pneumoconiosis. Wearing a dust mask is a key protective measure, which can filter out fine dust.

Conclusion

The process of processing magnesium oxide by Raymond mill covers raw material pretreatment, grinding, finished product packaging and other links. Each step requires technical and experience support. Choosing the appropriate Raymond mill, based on the type of magnesium oxide (light-burned/heavy-burned) and fineness requirements, can fully leverage the equipment's advantages, enhance efficiency and reduce costs.