Quartz sand, as a non-metallic mineral with a dominant SiO₂ content, has become a core raw material in industries such as glass manufacturing, photovoltaic semiconductors, water treatment, and ceramic refractory materials, thanks to its excellent properties including hardness, wear resistance, chemical stability, and high-temperature resistance. With the confirmation of new high-purity quartz ore species and the development of strategic emerging industries, the market's requirements for the purity and particle size accuracy of quartz sand have been continuously increasing. As a mature and efficient powder processing equipment, the Raymond mill, with its targeted process design, has become the preferred solution for large-scale and high-quality processing of quartz sand, providing stable and reliable raw material support for various industries.

The core advantages of Raymond mills in quartz sand processing

- Precise level control to meet diverse needs

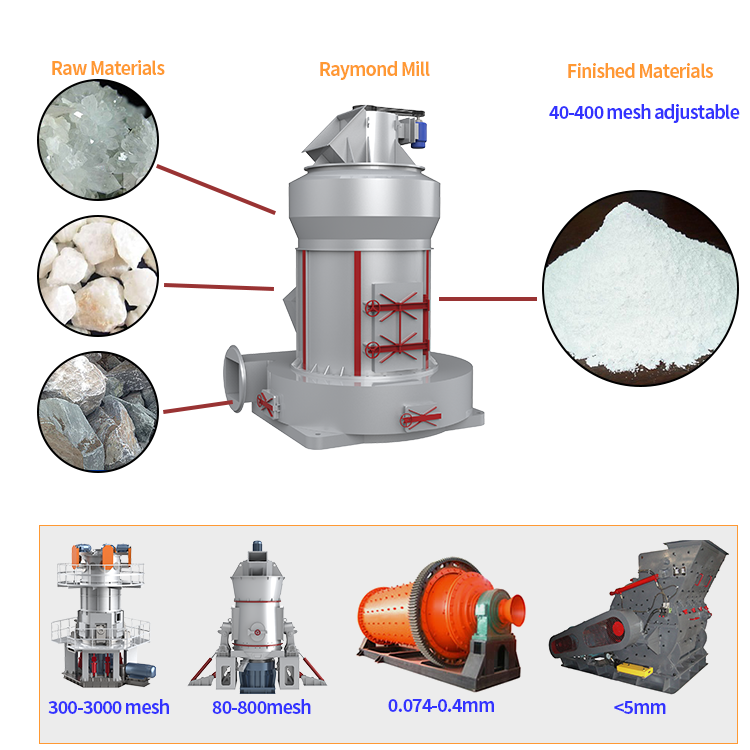

The particle size range of quartz sand is from 2-4 mesh to 2500 mesh. Different industries have significant differences in particle size requirements - high-purity quartz sand used in photovoltaic crucibles needs ultrafine powder, while water treatment filter materials require particles of specific sizes. By adjusting the rotational speed of the analyzer and the grinding gap, the Raymond mill can precisely produce products of conventional specifications ranging from 80 to 325 mesh and ultra-fine specifications from 400 to 2500 mesh. It can match the particle size standards of various products such as common quartz sand, refined quartz sand, and silicon micro-powder, and meet the usage requirements of different fields including glass, chemical engineering, and electronics.

- Efficient grinding, balancing output and energy consumption

Quartz sand has a Mohs hardness of 7, is wear-resistant and hard in texture, and has extremely high wear resistance requirements for processing equipment. The Raymond mill adopts high manganese steel grinding rollers and liners, and is equipped with a high-pressure spring pressurization structure. Its grinding efficiency is over 30% higher than that of traditional equipment. The output of a single unit can reach 1 to 20 tons per hour, making it suitable for small and medium-sized large-scale production. Meanwhile, the equipment adopts a closed-loop grinding system, featuring high air separation efficiency and a 15% to 20% reduction in unit energy consumption, effectively controlling production costs.

- Purification synergy ensures product purity

The core value of quartz sand lies in its SiO₂ purity. For ordinary quartz sand, it should be ≥90%, while for high-purity quartz sand, it should be above 99.5%. The Raymond mill processing flow can be seamlessly integrated with purification processes such as magnetic separation, scrubbing, and acid leaching. During the grinding process, a closed system is used to reduce external contamination, and the fine powder produced by grinding is precisely sorted by an analyzer to prevent impurity accumulation. For the processing of high-purity quartz sand, a dedicated iron removal device can be used to further reduce the content of impurities such as Fe₂O₃, ensuring that the product meets the purity requirements of high-tech fields such as photovoltaic and semiconductor industries.

- Environmentally friendly and green, in line with industrial trends

Dust pollution in quartz sand processing is a pain point in the industry. Long-term inhalation can cause occupational diseases such as silicosis. The Raymond mill is equipped with a high-efficiency pulse dust collector, with a dust removal efficiency of over 99.9%. The dust concentration in the workshop complies with national environmental protection standards. When the equipment is in operation, it adopts a noise reduction design, keeping the noise below 85 decibels. Meanwhile, a closed-loop circulation system reduces the escape of dust, which not only protects the health of the operators but also meets the requirements of environmental protection production, alline with the green development direction of the quartz sand industry.

Adapt to scenarios and industry values

Quartz sand products processed by Raymond mills have been widely applied in multiple fields:

Glass industry: Provide 80-120 mesh quartz sand to ensure the transparency and durability of flat glass and optical glass;

In the field of water treatment: Produce filter materials with specifications ranging from 0.5 to 2mm, meeting the sewage interception requirements of single-layer and double-layer filter tanks, and conforming to the upgrading and renovation requirements of sewage treatment plants.

Photovoltaic/semiconductor industry: Process 200-325 mesh high-purity quartz sand as the core raw material for quartz crucibles and silicon wafer manufacturing;

Ceramics and Chemicals: Supplying 120-200 mesh products for ceramic blanks and chemical grinding materials, enhancing the high-temperature resistance and wear resistance of products.

With the development and application of high-purity quartz ore, Raymond mills, with their advantages of flexible adaptation and high efficiency and environmental protection, will continue to assist the quartz sand industry in transforming from low-purity to high-purity and from traditional processing to green and intelligent processing, providing key raw material guarantees for strategic emerging industries.