In the field of powder processing, ferromagnetic impurities in materials not only affect product purity but also may accelerate equipment wear and trigger production safety hazards, becoming a key bottleneck restricting the improvement of enterprise production capacity and quality. As an efficient and automated iron removal device, the pneumatic magnetic separator has become the preferred solution for industries such as chemical engineering, food, medicine, and building materials, thanks to its core advantages of no need to stop the machine for cleaning, high iron removal accuracy, and adaptability to various working conditions.

Shanghai Cronus has been deeply engaged in the research and development and manufacturing of powder equipment for decades. Relying on its rich industry experience and technological accumulation, it has created a series of pneumatic magnetic separators, providing stable and reliable material purification guarantees for global customers.

I. Core Advantages of Pneumatic Magnetic Separators: Automated iron removal, with dual guarantees of efficiency and quality

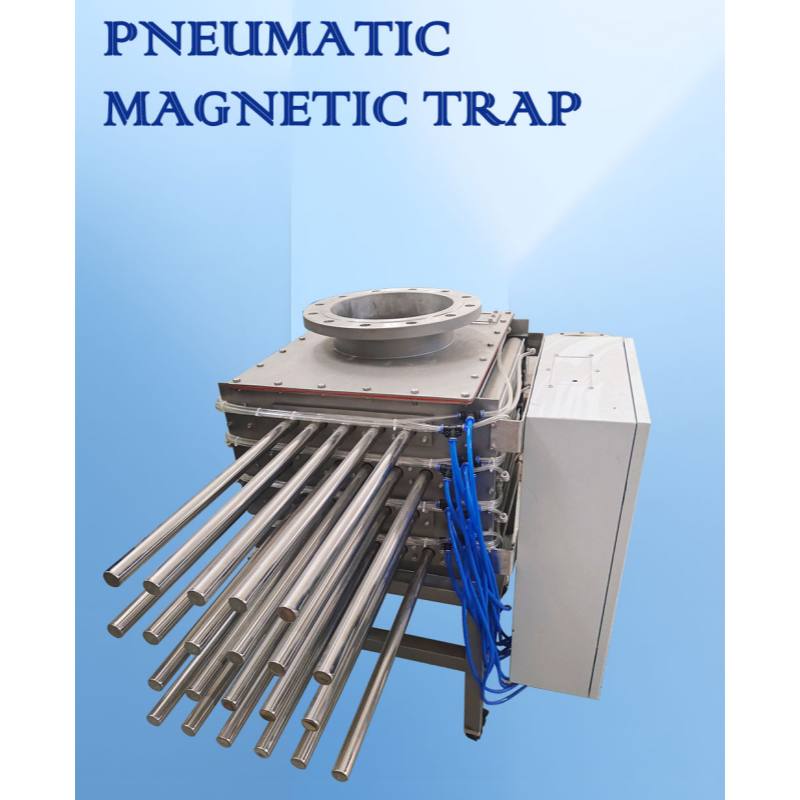

The pneumatic magnetic separator is a highly efficient iron removal device based on the principle of strong magnetic adsorption and driven by compressed air to automatically discharge iron. Its core advantage precisely matches the continuous production needs of modern industry:

Efficient and automatic cleaning, no need for shutdown or interruption

The cleaning mechanism is driven by high-pressure air at 0.4-0.6MPa. When the magnetic rod adsorbs iron impurities to the set threshold, the control system automatically triggers the pneumatic valve to push the magnetic rod group out of the flow channel and complete the purging and stripping. The entire response process takes less than 5 seconds. During the cleaning process, materials can pass through continuously, completely solving the pain point of manual cleaning with traditional magnetic separators, which requires machine shutdown and affects production capacity, and achieving 24-hour continuous operation.

Strong magnetic adsorption, with precision far exceeding industry standards:

The core magnetic rods are made of high-coercive rare earth neodymium iron boron material (N45 grade and above), with a peak surface magnetic field intensity of over 14,000 Gs. They can precisely capture fine iron powder, steel wire debris and other impurities under 0.1mm, achieving an iron removal cleanliness of over 98%, effectively meeting the purity requirements of high-end powder products.

Adapted to diverse working conditions, flexible and convenient installation

The product adopts a modular design and can be flexibly installed at key nodes such as vertical pipelines, silo outlets, and vibrating screen outlets, making it suitable for various material types including dry powder, granular, and sheet materials. For special working conditions such as high temperature and corrosiveness, we offer customized models with a temperature resistance up to 350℃. The magnetic rod housing is made of SS316L material, which has excellent wear resistance and corrosion resistance, thus extending the service life of the equipment.

Low consumption and energy saving, controllable operation and maintenance costs

No additional excitation power supply is required. It operates automatically relying on a pneumatic system, and its energy consumption is reduced by 30% to 40% compared with traditional electromagnetic iron removers. The magnetic rod has a low demagnetization rate and a service life of over 10 years. Coupled with a minimalist maintenance process, it significantly reduces the labor and equipment replacement costs for enterprises.

Ii .Shanghai Cronus's strong support: Decades of experience in powder equipment, a provider of customized solutions

In pneumatic magnetic separator R&D and manufacturing, Cronus offers tailored solutions for different industries: For hygiene in food and pharmaceuticals, sanitary-grade welding eliminates dead corners and meets safety standards. For high-volume needs in chemicals and building materials, an optimized alternating magnetic rod layout increases material contact and iron removal efficiency. For harsh conditions like mining tailings or plastic recycling, enhanced seismic and dust-proof design ensures stable operation.

With strict raw material screening and precise production process control, Shanghai Cronus pneumatic magnetic separators have passed multiple industry certifications. The products not only cover all provinces and cities in China but are also exported to many countries and regions around the world, and are widely used in key scenarios such as calcium hydroxide production lines, powder coating processing, food raw material purification, and pharmaceutical intermediate purification. After a certain building materials enterprise introduced our company's pneumatic magnetic separator, the iron impurity content in the materials decreased by more than 90%, the equipment wear rate dropped by 40%, and the product qualification rate increased to over 99.5%, significantly enhancing its core competitiveness.

Iii. All-scenario Adaptation + Full-service: Choosing Shanghai Cronus is more than just about quality products

Shanghai Cronus has a deep understanding of the individualized demands of different industries and provides customers with full-process services ranging from the initial research on working conditions and product selection to the later installation, commissioning and operation and maintenance guidance.

- Customized selection: Our professional technical team precisely matches the optimal model based on the customer's material characteristics (humidity, particle size, iron content), production capacity, installation space and other parameters. When necessary, we provide exclusive customized development services.

- Standardized installation: Provide detailed installation guidance manuals and on-site technical support to ensure that the equipment can quickly adapt to the existing production line and achieve seamless connection.

- Full-cycle operation and maintenance: Establish a complete after-sales service system, providing services such as regular equipment inspection, rapid response to faults, and timely supply of spare parts to ensure the long-term stable operation of the equipment.

Under the trend of industrial automation, efficient, stable and intelligent production equipment has become the core driving force for enterprises to reduce costs and increase efficiency. Shanghai Cronus pneumatic magnetic separators, with automated iron removal capabilities at its core, customized solutions as its support, and full-cycle services as its guarantee, help customers in various industries break through iron removal bottlenecks, improve product quality and production efficiency.

For more information on the product parameters, application cases or customized solutions of pneumatic magnetic separators, please visit the official website of Shanghai Cronus or call for consultation. We will provide you with professional material purification solutions.