Jaw Crusher

Jaw crusher in stone crusher machine is a commonly used mining machinery and equipment, which crushes larger stones or ores by squeezing the fixed jaw plate and the movable jaw plate against each other. Its main function is to reduce the size of the mined ore for processing or transportation. Jaw crusher is effective in mines, quarries and recycling processes where large pieces of material need to be broken. This crushing equipment is widely used in mining, metallurgy, building materials, construction and other industries.

Double Rollers Crusher

Double Rollers Crusher in stone crusher machine a mechanical device that uses two rollers rotating relative to each other to crush materials. The materials entering between the rollers are crushed into the required particle size through compression and shearing between the rollers. At the same time, it is also equipped with a special mechanical system to deal with the situation where unbreakable objects enter the crushing chamber, so as to protect the equipment and maintain its normal operation.

How a double roll crusher works

Operating a double roll crusher is very simple. Whether single or double drive, the rolls are driven by an electric motor and V-belt drive, resulting in reliable and quiet operation. In the case of a single drive, power is transferred from the drive roll to the non-driven opposing roll via an interstage V-belt drive. In the case of a double drive, each roll is driven independently via an electric motor and V-belt drive.

During normal operation, the material is fed between the crushing rolls. The compression and shear forces generated between the opposing rolls reduce the feed material to the desired product size while producing a cubic product with a minimum of fines.

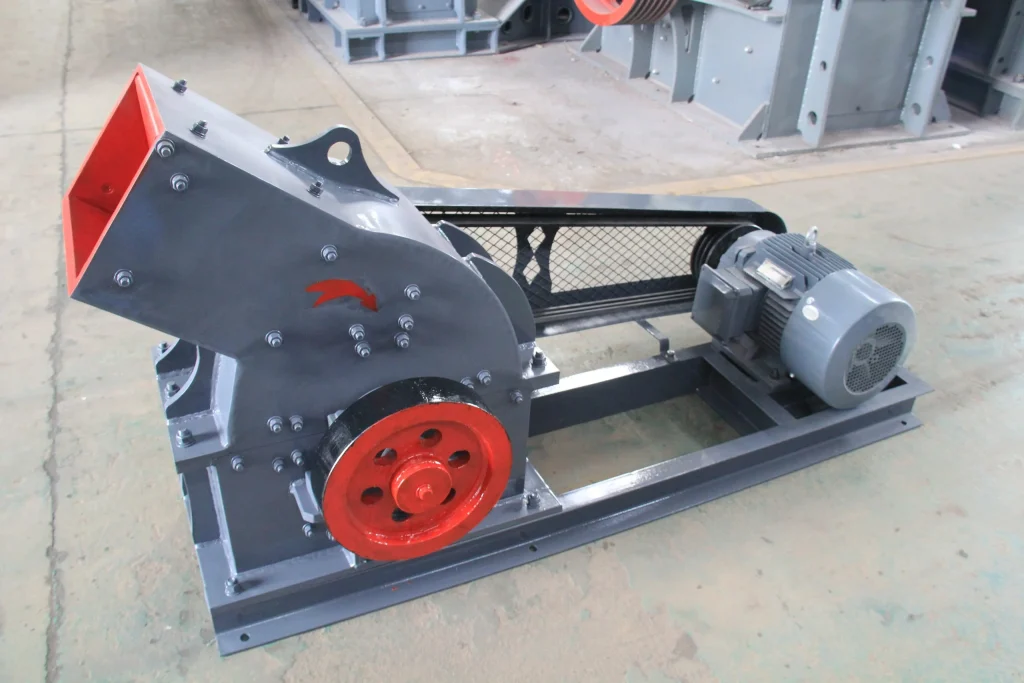

Hammer Crusher

Hammer crusher in stone crusher machine is a small and medium-sized hammer crushing equipment with a feed opening size of 400mm×300mm. This equipment is suitable for crushing medium-hardness and brittle materials. The equipment has a simple structure, easy operation and high crushing efficiency. It is an ideal choice for industries such as mining, building materials and chemicals.

Working Principle of the 400×300 Hammer Crusher

- Feeding:

Material enters the crushing chamber through the feed inlet and is evenly distributed around the rotor. - Crushing:

The high-speed rotating hammers impact, shear, and collide with the material, breaking it down to the desired size. - Screening:

Crushed material passes through the screen plate, while oversized material remains in the chamber for further crushing. - Discharge:

Material meeting the size requirements is discharged from the outlet, completing the crushing process.

If you need an efficient and reliable stone crusher machine in your project, please feel free to contact Cronus. Whether it is equipment selection, technical consultation, or after-sales guarantee, I will tailor a solution for you with a professional attitude and perfect service system to help the project go smoothly. I look forward to working with you to open up a new chapter in your career!