Talcum powder for industrial and pharmaceutical use. Its main component is hydrated magnesium silicate (chemical formula: Mg₃Si₄O₁₀₂), which is a type of silicate mineral. Talc is made by crushing, grinding, treating with hydrochloric acid, washing and drying talc ore. It has a white or off-white fine powder appearance, soft and smooth texture, greasy feel, odorless and tasteless, and insoluble in water, dilute hydrochloric acid or sodium hydroxide solution.

The physical properties of talc include low hardness (1.0~1.5 Mohs hardness), high melting point (up to 1300℃), good insulation, chemical stability, and low thermal conductivity and electrical conductivity. These properties make it widely used in many fields, such as medicine, cosmetics, papermaking, ceramics, rubber, coatings and other industries

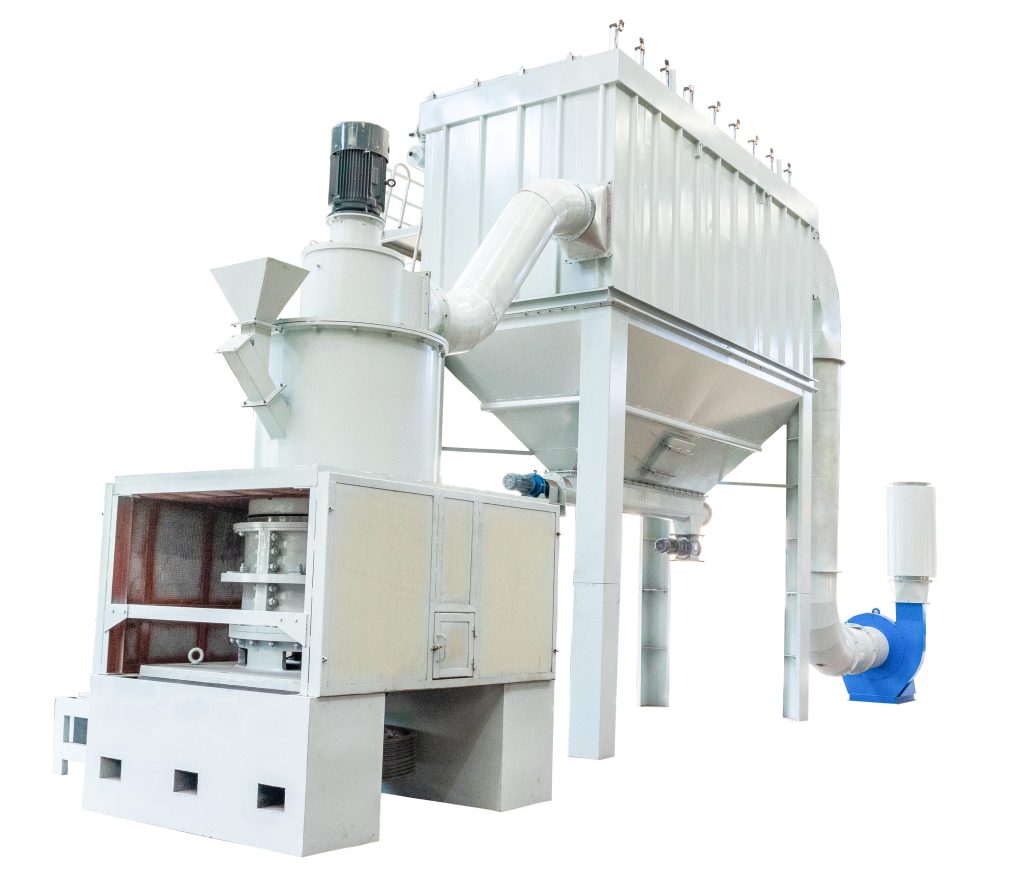

CRLMX1200 Ultrafine Vertical Grinding Mill

Product fineness: 325~1500 mesh

Product capacity: 3.8~12t/h

Application scenario:

The equipment is suitable for ultra-fine grinding of non-metallic minerals such as calcite, marble, limestone, heavy calcium, talc, barite, dolomite, etc.; it can provide high-quality fillers and additives for papermaking, plastics, coatings, rubber, inks, chemicals and other industries.

Functional characteristics of ultrafine vertical mill

The equipment is widely used in ultrafine grinding of non-metallic minerals such as calcite, marble, limestone, heavy calcium, talc, barite, dolomite, etc.; product fineness: 45~8μm (325~1500 mesh), production capacity: between 3.8~16t/h; it can provide high-quality fillers and additives for papermaking, plastics, coatings, rubber, inks, chemicals and other industries. It integrates ultrafine grinding, modification, ultrafine grading and conveying collection, and has the advantages of stable and reliable operation, high grinding efficiency, stable product quality, strong equipment applicability, overall sealing of the system, full negative pressure operation, no dust spillage, easy maintenance, low operating costs, etc. Its process parameters and performance indicators are close to the international advanced level.

Product advantages of ultrafine vertical mill

Stable and reliable operation, high grinding efficiency, stable product quality, strong equipment applicability, overall sealing of the system, full negative pressure operation, no dust spillage, easy maintenance, low operating cost, various process parameters, performance indicators, etc. are close to the international advanced level.

Talc powder product varieties and uses

◆Cosmetics

Talc is a high-quality filler in the cosmetics industry. Due to its high silicon content, it has the function of blocking infrared rays, enhancing the sun protection and anti-infrared properties of cosmetics. Talcum powder is often used in the preparation of various moisturizing powders, beauty powders, talcum powders and other products.

◆Coatings

In coatings, talcum powder is mainly used in primers and intermediate paints, such as flash primers and paints for transportation vehicles. Talcum powder is often preferred; primers for steel structures can use talcum powder in whole or in part to improve its sedimentation, coating mechanical strength and re-coating properties; polyurethane waterproof coatings often add talcum powder, which can reduce the volume shrinkage of waterproof coatings during curing, improve their wear resistance and adhesion, and reduce costs. It also makes the coating have good stability and heat resistance and prolongs the storage time.

◆Papermaking

Adding talcum powder in the papermaking industry helps to improve filler retention and improve paper transparency, smoothness and printability, and makes the paper have higher ink absorption. Talc has stable chemical properties and is not only suitable for papermaking under acidic conditions, but can also be used in conjunction with calcium carbonate for papermaking under neutral conditions. Talc has a good combination with sizing agents, so it can effectively improve the retention of sizing agents, reduce the absorbency of paper sheets, and prevent printing ink from penetrating paper sheets.

◆Plastics

Talc is an effective reinforcing material in plastics, which can make plastics have strong rigidity, creep resistance and solid gloss regardless of room temperature or high temperature conditions. The addition of talcum powder changes many properties of plastics, such as surface hardness, tensile strength, bending modulus, molding shrinkage, impact strength, thermal deformation temperature, product dimensional stability, etc.

Adding talcum powder to polyethylene and polypropylene plastics can effectively improve the surface hardness and surface scratch resistance of the products. In addition, the price of talcum powder is 10%~20% of that of plastics, so applying talcum powder to the plastics industry can also reduce costs.

◆Rubber

In the automotive industry, replacing part of carbon black with talcum powder can improve the heat resistance of rubber; in the industrial rubber products or hose industry, it will not damage the performance of the rubber compound (such as air conditioning refrigerant); in products such as door and window seals, talcum powder can reduce the impact and damage of climatic conditions on rubber performance.

◆Cable

Talc insulation material has a long history of use in the cable industry. Talc can minimize electrolytic degradation or even completely eliminate it, which is very important for coolant hoses.

◆Ceramic

In the ceramic industry, talcum powder plays an important role. The reason why ceramics show different colors is that talcum powder is added to them. Different proportions and different composition ratios can make ceramics show different colors, and at the same time, they can make the density of ceramics uniform, the surface smooth, and the gloss good after calcination.

◆Textiles

Ultrafinely ground talcum powder is often used as a filler and bleaching agent in some textiles, such as waterproof cloth, fireproof cloth, wheat flour bags, rope nylon, etc., which can enhance the density of the fabric and enhance the heat resistance and acid and alkali resistance.

Application of talcum powder in preparations

◆ Powder coating layer

In sugar coating, talcum powder can be used for powder coating layer. White talcum powder that passes through a 100-mesh sieve is preferred. The dosage is generally 3%~6%. It can not only eliminate edges and corners to facilitate coating, but also improve the stability of sugar-coated tablets.

◆ Used as a lubricant

Since talc has a layered structure that is easy to split into scales, it can be used as a lubricant to improve the compression molding and fluidity of drug powders. Talc can fill the depressions on the surface of drug powders, thereby reducing the friction between drug powders and improving the fluidity of drug powders.

◆ Used as a filter aid

Talc powder is not easy to react with drugs and has a certain adsorption capacity, so it can be used as a filter aid. Talc powder activated at 115℃ can be added to the drug solution while hot to adsorb a small amount of polysaccharides, mucus, and gum impurities, and will hardly destroy the active ingredients of the drug itself.