In the process of steel production, a common by-product is generated - steel slag. In the past, most of these steel slags were directly piled up, which not only occupied a large amount of land but also might cause environmental pollution due to rainwater erosion and other factors, becoming an "environmental burden" for the steel industry. But in fact, steel slag is not useless waste. As long as it is scientifically processed, it can be transformed into high-value industrial raw materials. Today, let's talk about how steel slag is resourcefully utilized through grinding technology and the key equipment used behind it.

Steel slag has a complex composition: it mainly comes from oxides (e.g., silicon, aluminum, manganese) from oxidized metal furnace charges, plus impurities (sand, mud) in metal materials, slag-forming materials (lime, fluorite) added in production, and eroded furnace linings or deoxidation products.Despite this complexity, steel slag is a "treasure": it contains over 50% dicalcium silicate (C₂S) and tricalcium silicate (C₃S) (matching Portland cement clinker’s core components), plus unique minerals like olivine (CRS) and rosinite (C₃RS₂). These give it excellent properties: wear resistance, corrosion resistance, and low hydration heat.

Steel slag micro-powder has a wide range of uses after processing. It is mainly applied in cement production. After being added, it can be made into various special cements, reducing the amount of clinker used, lowering costs, and enhancing the wear resistance and durability of cement. It is suitable for roads and large-scale projects. In addition, steel slag micro-powder can also be compounded with slag powder to be used as a concrete admixture, enhancing the strength and durability of concrete. It is often applied in key projects such as high-rise buildings, Bridges and tunnels.

To achieve the above applications, the steel slag needs to be "ground finely" to enhance its activity. After steel slag is mechanically ground into powder, the activation energy on the particle surface increases and its activity improves. When ground to a specific surface area of 300 to 400m³/kg, it can be used as a highly active admixture. If ground to a mesh size of over 400, it has better compatibility with cement. In concrete, it can replace cement at a proportion of no more than 20%, which can enhance the strength and pumpability of concrete.

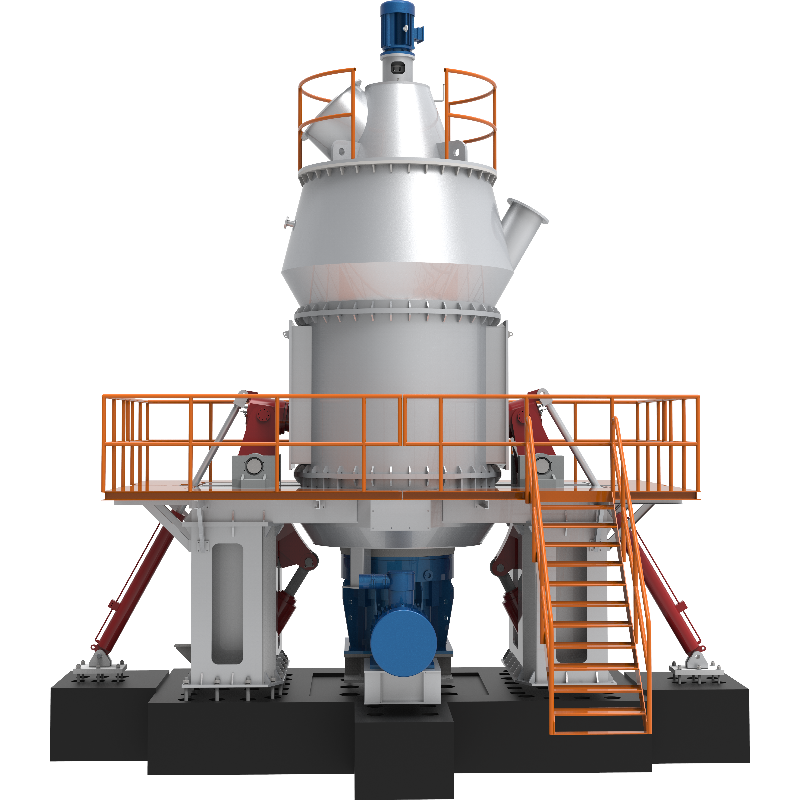

Steel slag has high hardness and poor grindability. There are many problems with traditional ball mills for grinding steel slag, such as high energy consumption, with electricity consumption of 70 to 80kW·h per ton of product, which leads to high costs. Moreover, the production capacity is low and the fineness of the finished products is uneven, which affects the subsequent application effect. Therefore, to efficiently process steel slag, specialized grinding equipment is required. At present, the CRLM series vertical grinding mill and CRRM series Raymond grinding mill developed by Shanghai Cronus are specialized equipment designed for difficult-to-grind materials like steel slag.

What are the special features of the dedicated grinding equipment?

Take the CRLM series vertical mill as an example. This equipment integrates five major functions: crushing, grinding, drying, powder selection and conveying. It does not require the collaboration of multiple devices, making the process more concise. It adopts the principle of material bed grinding, which can save 30% to 50% of energy compared with traditional ball mills, significantly reducing energy consumption costs. In addition, the fineness of the finished product can be flexibly adjusted within the range of 80 to 600 mesh, stably producing highly active steel slag micro-powder. With a large single-machine output, it is suitable for large and medium-sized steel slag resource utilization projects.

The CRRM series Raymond mills are more suitable for small and medium-sized projects. They have low investment costs, small floor space, and the fineness of the finished products and production capacity can both meet the needs of small-scale production. This equipment can also be upgraded to a sand and powder integrated machine as needed, enabling simultaneous grinding and sand-making of steel slag, further enhancing the comprehensive utilization rate.

The Cronus grinding equipment focuses on environmental protection and is equipped with an efficient dust collection system to control dust emissions. The resource utilization of industrial solid wastes such as steel slag has become a trend. Through grinding technology, it is transformed into high-quality building material raw materials, which not only solves the environmental protection problem but also realizes resource recycling.

The transformation of steel slag from "waste" to "resource" hinges on the advancement of grinding technology. With the continuous upgrading of technology, the resource utilization efficiency of steel slag will be further enhanced, contributing greater value to the development of green industry.