Wollastonite exhibits excellent chemical corrosion resistance, thermal stability, and dimensional stability. It possesses a glassy to pearly luster, low water absorption and oil absorption, as well as outstanding mechanical and electrical properties. It is primarily used as a reinforcing filler in polymer-based composite materials, serving as a raw material or filler in industries such as papermaking, ceramics, cement, rubber, and plastics.

Coating-grade wollastonite powder offers good reinforcement properties, improving the toughness and durability of coatings while maintaining surface smoothness and good gloss. Plastic and rubber-grade wollastonite, with its unique acicular fiber structure, provides excellent insulation, wear resistance, and a high refractive index. Construction-grade wollastonite powder, being non-toxic, odorless, and non-radioactive, is gradually replacing asbestos—which is harmful to human health—becoming a new environmentally friendly raw material for construction in the new century. Ceramic-grade wollastonite powder, when added in appropriate amounts to ceramic raw materials, can significantly reduce firing temperatures, shorten firing times, and enable low-temperature rapid single firing.

Therefore, as a filler raw material in the plastics, rubber, ceramics, coatings, and construction industries, wollastonite powder holds increasing value and promising market prospects.

Practitioners in the wollastonite industry can use Raymond mills to process and grind wollastonite into powder ranging from 10 to 325 mesh, which can then be applied in related industries to generate value. However, wollastonite powder processed by ordinary grinding mills tends to meet lower standards, resulting in relatively low selling prices. Additionally, many mining enterprises only sell raw ore to maximize profits, reducing costs but inevitably diminishing returns.

In this field, those familiar with the situation are aware that the price of wollastonite exported from China to other countries differs by up to ten times compared to the price of wollastonite powder imported back from the United States and Japan. This staggering gap highlights the distinction in product specifications, underscoring the value difference between ordinary wollastonite powder and ultra-fine powder.

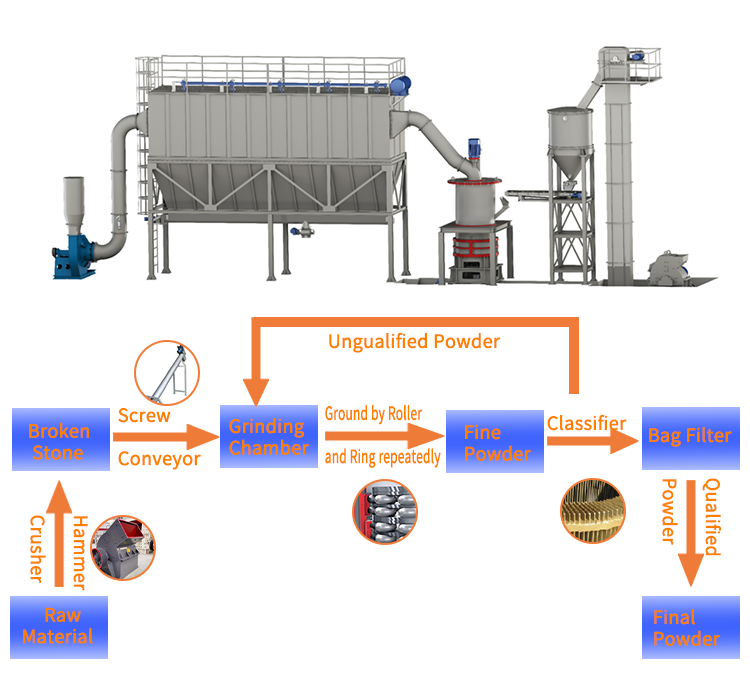

The ultra-fine grinding mills manufactured by Cronus can process wollastonite powder in the range of 200 to 3000 mesh, making it highly effective as a filler. Additionally, we provide customers with a complete set of production line equipment, including crushing, grinding, conveying, and packaging, and design process solutions based on customer requirements to enhance the grade and quality of wollastonite.