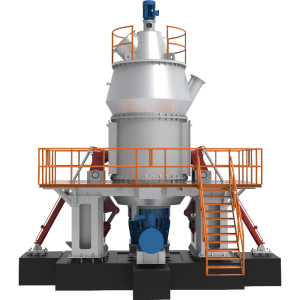

Vertical roller mill is a high-efficiency and energy-saving grinding equipment, which is widely used in cement, power, metallurgy, chemical industry and other industries. Its working principle is based on material bed grinding technology, and material crushing is achieved through the extrusion and shearing action between the grinding disc and the grinding roller. Compared with traditional ball mills, vertical roller mills have higher energy utilization efficiency and more precise particle size control capabilities.

Cement vertical mill: core equipment and structural analysis of cement production

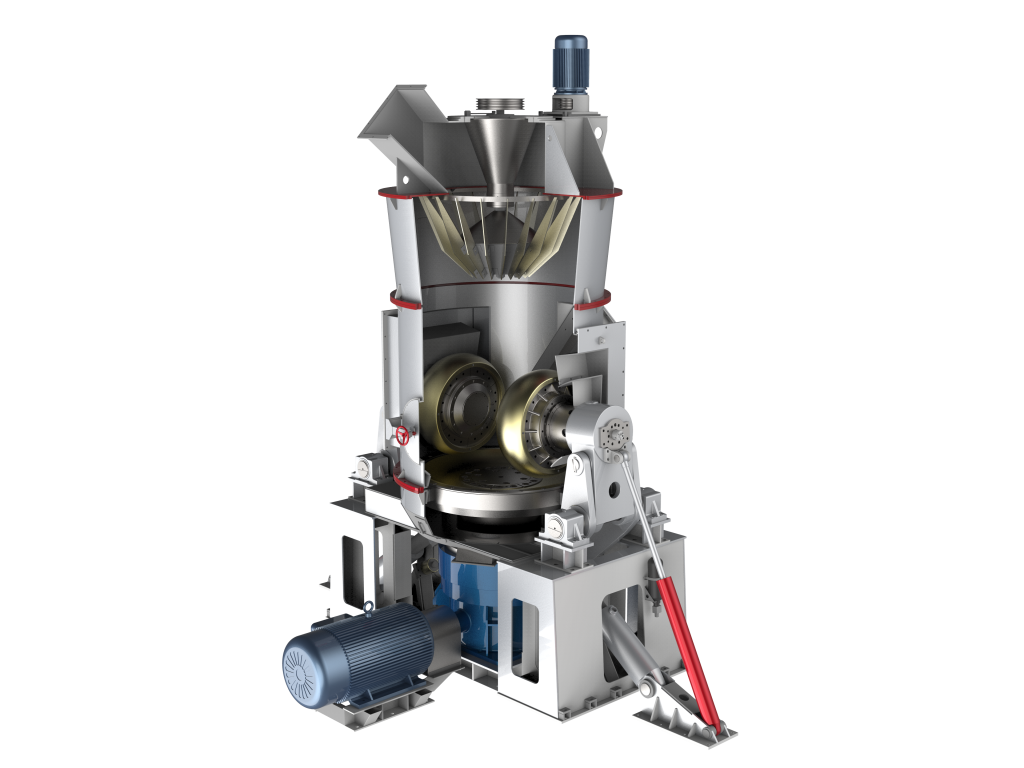

The grinding disc is the main grinding component. The rotating disc made of highly wear-resistant material can withstand long-term grinding; the grinding roller is located above the grinding disc, and exerts pressure and shear force on the raw materials through hydraulic control to achieve optimal grinding efficiency. These two components work in tandem to form the core of the grinding process, ensuring raw materials are effectively processed into the desired consistency.

The lubrication system continuously provides lubrication and cooling for the grinding roller and grinding disc to prevent equipment overheating and reduce wear; the feeding and discharging system accurately controls the input and output of materials to ensure uniform distribution and maintain stable grinding performance; the powder selector is responsible for classifying the ground particles to achieve the required fineness; the hydraulic system and drive unit dynamically adjust the roller pressure and high-torque motor and gearbox to ensure the smooth rotation of the grinding disc and achieve efficient grinding. These supporting systems collaborate seamlessly, enhancing the overall performance and reliability of the cement vertical mill.

Technical advantages of vertical roller mill in cement grinding

Significant energy efficiency advantage

The power consumption of vertical roller mill is 30%-50% lower than that of traditional ball mill, which is mainly due to its unique material bed grinding principle, which reduces ineffective power consumption and reduces over-grinding through built-in high-efficiency powder selector. In addition, the system resistance is small and the fan power consumption is low, which further improves the overall energy efficiency.

Excellent product quality

The vertical roller mill can produce finished products with reasonable particle distribution and low temperature, which is conducive to improving the strength of cement. At the same time, its fineness adjustment is flexible and can meet the production needs of different varieties.

Operation and maintenance advantages

The vertical roller mill has low noise (15-20 decibels lower than the ball mill), small footprint, compact layout, low metal consumption, and long life of wear-resistant parts. In addition, the equipment has a high degree of automation, less operator requirements, and reduced labor costs.

Outstanding environmental protection performance

The vertical roller mill system is fully enclosed, with less dust emission and less noise pollution. At the same time, it has a large drying capacity, can handle water-containing materials, reduce drying energy consumption, and meet modern environmental protection requirements.