Core performance and powder quality are the most direct indicators for measuring its technical grade.

Fineness of the finished product

Range and adjustability: Cronus' Raymond mill should be capable of producing products with a wide fineness range of 80 to 325 mesh, and can be flexibly and stably controlled by adjusting the speed of the analyzer.

Uniformity: The particle size distribution of the finished powder should be concentrated to avoid overly coarse or fine particles, ensuring the uniformity of the product.

The production capacity is 1 to 80 tons per hour

The output of Cronus' Raymond mill is approximately 1 to 80 tons per hour. Under the same material, fineness and power consumption conditions, the higher the output, the higher the grinding efficiency and classification efficiency of the mill.

Poor-quality equipment often fails to reach the rated output or its output drops rapidly as the equipment wears out.

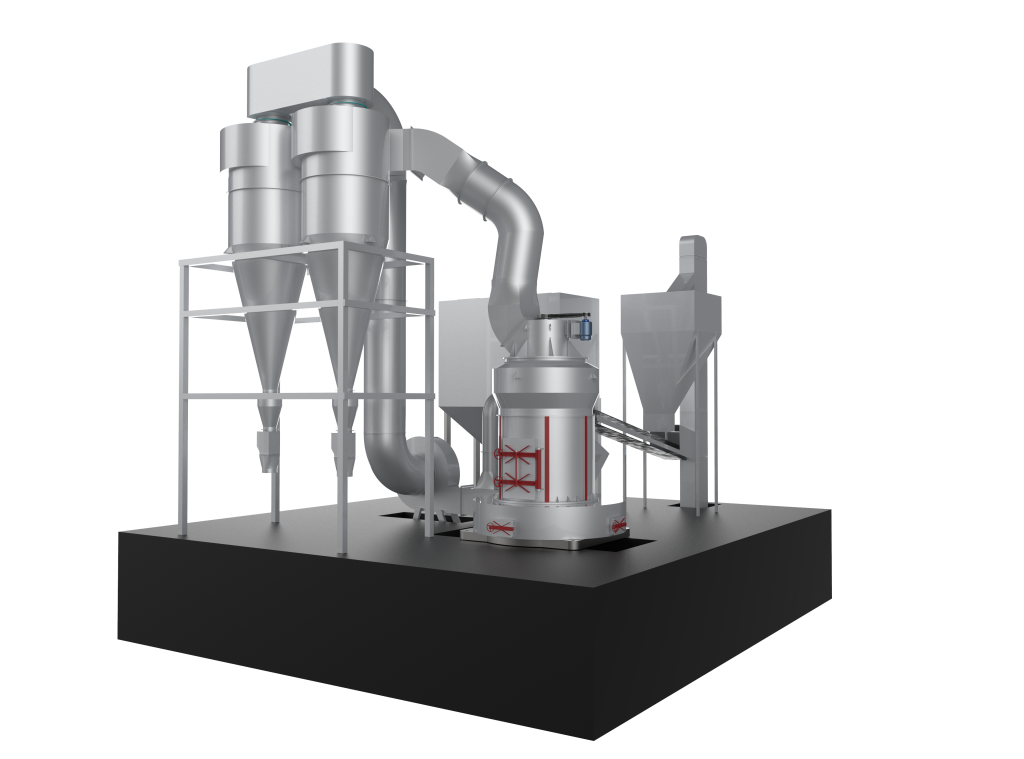

II. Mechanical Structure and Manufacturing Quality

This determines the durability, stability and lifespan of the equipment.

Grinding rollers and grinding rings

Material and hardness: This is the core component that is most prone to wear. Cronus uses high-quality grinding rollers and grinding rings made of wear-resistant materials such as high manganese steel and high chromium alloy steel, and undergoes special heat treatment (such as quenching), which endows them with extremely high hardness and wear resistance. Service life is the key to measuring its quality.

Structural design: A reasonable surface design of the grinding roller can enhance the grinding efficiency.

Main shaft and drive system

Main shaft strength: The main shaft must have sufficient strength and rigidity to withstand huge grinding forces and ensure smooth operation without vibration.

Transmission efficiency: The adopted reducer and flat belt have high transmission efficiency, smooth operation and low noise.

Analysis machine (classifier)

This is the core component that controls the fineness of the product. The high-quality analytical machine has a reasonable blade design, precise and stable speed regulation, and high classification efficiency. It can effectively separate qualified fine powder and prevent coarse particles from being mixed into the finished product.

The quality of a Raymond mill cannot be judged by a single parameter. Choosing Cronus means you are choosing an outstanding solution that integrates higher efficiency, lower overall operating costs, longer service life and more stable powder output quality - this is precisely the high-quality connotation that Cronus defines for you.