Definition of Pulverized Coal

Pulverized coal consists of fine particles with varying sizes and irregular morphologies. The particle diameter typically ranges from 0 to 1000 μm, with the majority falling within the 20–50 μm range. The bulk density of freshly ground pulverized coal is approximately 0.45–0.5 t/m³; after storage for a certain period, it increases to 0.8–0.9 t/m³ due to compaction. Pulverized coal exhibits fluid-like behavior owing to its fine particle size and high specific surface area, which enables significant adsorption of air on particle surfaces. This characteristic facilitates pneumatic conveying. However, it may also lead to unintended flow (self-flow) and powder leakage in cases where equipment sealing is inadequate.

Primary Applications in the Chemical Industry

Pulverized coal is a combustible material classified as a Class B fire hazard. Its dust is explosive, with an ignition temperature ranging between 300°C and 500°C. The lower explosive limit (LEL) concentration of coal dust is 34–47 g/m³, based on an average particle size of 5–10 μm. For accumulated dust layers (approximately 5 mm thick), the auto-ignition temperature ranges from 225°C to 285°C, whereas for suspended (cloud-like) dust, the ignition temperature is higher, at 580°C to 610°C.

Main Suitable Raw Materials (Coal Types) for Pulverized Coal Processing

Not all coal types are suitable for pulverized coal processing; raw material selection depends on the quality requirements associated with the intended application.

1. Bituminous Coal

This is the most widely used and primary feedstock for pulverized coal production.

Characteristics: High volatile matter content, excellent reactivity, and favorable combustion performance.

Applications: Commonly employed across various industries, including power generation, cement manufacturing, and blast furnace injection.

2. Poor Coal and Lean Coal

Characteristics: Lower volatile matter content compared to bituminous coal, but higher fixed carbon content and calorific value.

Applications: Utilized in specific cement kilns or boilers with particular operational requirements.

3. Lignite

Characteristics: High moisture content, very high volatile matter, relatively low calorific value, and a tendency toward spontaneous combustion.

Applications: Primarily used for power generation in pithead power plants. Due to its good formability, lignite is often processed into briquettes or water-coal slurry. Direct pulverization into coal powder is less common due to high drying costs and elevated storage risks.

Coal Types Not Suitable or Requiring Special Treatment

Anthracite: Owing to its extremely low volatile matter content, anthracite is difficult to ignite and sustain stable combustion, making it generally unsuitable for conventional pulverized coal boilers. However, it can be utilized in specially designed systems, such as certain cement vertical mills or as supplementary fuel in blast furnace injection, following specialized pretreatment.

Summary: Bituminous coal is the most commonly used raw material in pulverized coal processing, as it offers the optimal balance among ignitability, economic efficiency, and operational safety.

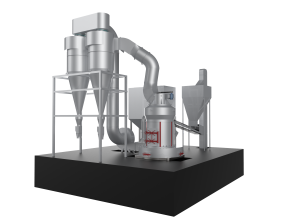

Coal Powder Processing Technology

The coal powder produced using Cronus equipment features uniform particle size distribution and consistent morphology. Typically, particle diameters range from 0 to 1000 μm, with most particles measuring between 20 and 50 μm. Additionally, the equipment demonstrates high throughput and low energy consumption, making it an ideal solution for efficient coal powder processing.

Stage One: Primary Crushing

In mineral processing, large raw materials are initially reduced in size using a primary crusher.

Stage Two: Secondary Crushing

Following primary crushing, the material is conveyed to impact crushers or cone crushers for further size reduction.

Stage Three: Grinding

After secondary crushing, properly sized material is fed into a grinding mill for pulverization. Oversized particles are recirculated via belt conveyors back through the crushing stages until they meet the required specifications, after which they proceed to grinding.

Stage Four: Product Storage

Finished coal powder must be stored in designated, controlled environments to ensure quality preservation and operational safety.

Pulverized coal, as a highly efficient micro-powder fuel processed from specific coal types, its unique particle characteristics, fluidity and flammability and explosiveness determine its irreplaceable core position in industrial fields such as metallurgy, power, building materials and chemical engineering. A thorough understanding of the characteristics and safety regulations of pulverized coal is a prerequisite for achieving its efficient, economic and safe application.

With the continuous improvement of energy efficiency and environmental protection requirements in industrial technology, the fine processing and clean utilization technology of pulverized coal will continue to evolve, providing a strong impetus for the development of modern industry.