Humic acid is a key raw material in industries such as organic fertilizers, petroleum additives, and cosmetics. The quality of its powder directly determines the performance of the final product. However, during the processing, the three major pain points of fineness control, humidity influence, and activity maintenance often cause headaches for enterprises. Today, we will break down for you: what kind of machine should be used to grind humic acid and how to choose the right equipment without making mistakes.

I. Three core pain Points in Humic Acid Processing

Many enterprises encounter problems such as "substandard fineness", "fluctuating output", and "insufficient activity of finished products" during processing. The root cause actually lies in three core challenges:

Fineness sensitivity: The particle size requirements for 60-mesh soil conditioners and 325-mesh medical-grade products are vastly different, making it difficult for ordinary equipment to adapt flexibly

Humidity problem: When the moisture content of raw materials exceeds 6%, traditional crushers are prone to clogging, and the output drops directly by 30%

Thermal sensitivity characteristics: Excessive heating during processing will destroy the active components of humic acid, reduce the organic matter content, and affect the product quality

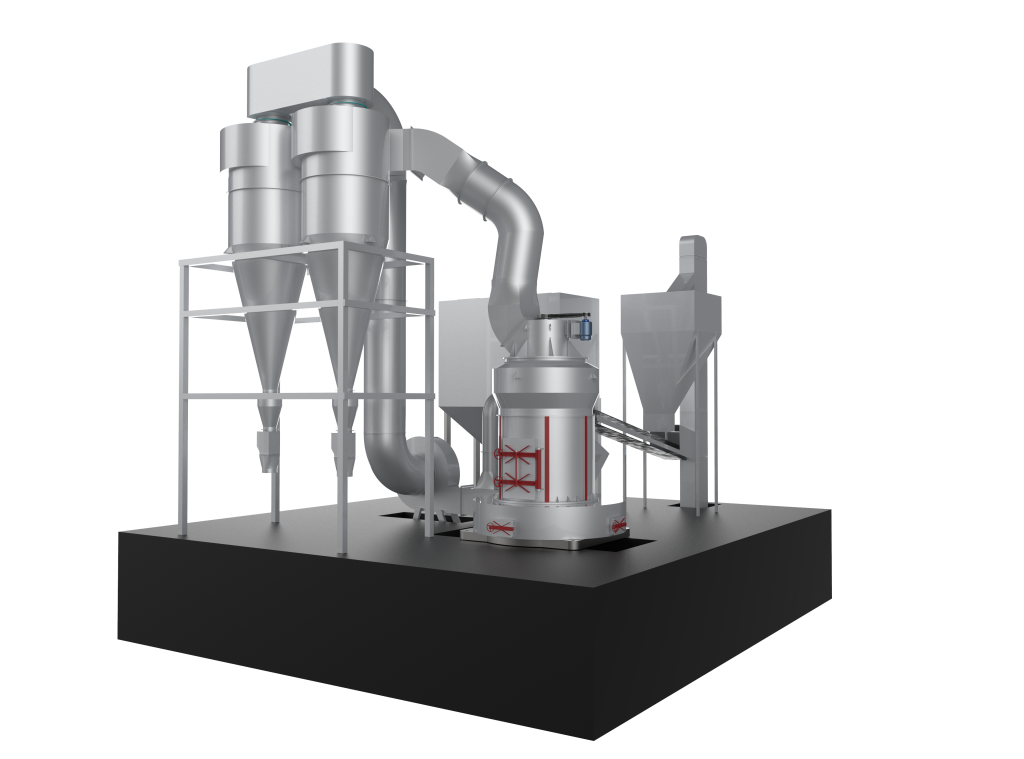

Ii. Raymond Mill: The "Evergreen Tree" in Humic Acid Processing

Among various crushing equipment, the Raymond mill has become the mainstream choice for humic acid processing with an 81% market share. It can precisely solve the above-mentioned pain points, which is also the core reason why 80% of enterprises choose it.

The three major advantages of the Raymond mill being compatible with humic acid

The crushing principle of the Raymond mill is highly compatible with the characteristics of humic acid, and it has significant advantages over traditional equipment:

High humidity tolerance: Equipped with a built-in circulating air duct system, it can directly process raw materials with a moisture content of up to 8%, eliminating the need for additional drying processes and reducing production costs

Wear-resistant, durable and more worry-free: High-chromium alloy grinding rollers are adopted, with a service life of 5 to 10 months, which is 6 times that of high-speed crushers, reducing the frequency of downtime for maintenance

Energy-saving and highly efficient with data: A case from a certain organic fertilizer factory in Liaoning Province shows that when using a Raymond mill to process 200-mesh humic acid powder, the hourly output remains stable at 1.8 to 2.2 tons, and the power consumption per ton is only 28 kilowatt-hours, a 22% decrease compared to before the transformation

Cronus Improved Raymond Mill: More efficient with technological upgrades

In response to the shortcomings of traditional equipment, Cronus has launched an improved Raymond mill, bringing humic acid processing into an era of high efficiency:

Vertical transmission is more energy-efficient: Transmission efficiency is increased by 18%, and energy consumption is directly reduced by 10-15%

Air duct optimization reduces powder accumulation: The curved surface air duct design lowers the powder accumulation rate of the pipeline by 35% and extends the maintenance cycle to 1,000 hours

Intelligent fineness control is more stable: The intelligent constant pressure system automatically compensates for the pressure of the grinding roller, narrowing the fineness fluctuation range to ±20 mesh, meeting the needs of different scenarios

Three Golden Rules for Selection: Avoid Pitfalls and Be Efficient

To maximize the benefits, choosing the right Raymond mill model is essential. Remember these three rules and you won't go wrong:

- The model is determined by scale and offers the best cost performance

Select suitable models based on annual output to avoid waste or insufficiency of production capacity

Annual output less than 10,000 tons: Choose 3R2615 Raymond mill, with outstanding cost performance

Annual output ≥ 30,000 tons: Choose the Cronus improved Raymond mill. The energy-saving benefits can be recovered from the equipment price difference within 18 months

- Fineness depends on the application, precise matching without waste

Different application scenarios have different requirements for fineness. Configuring as needed is more reasonable

Soil conditioner (60-100 mesh) : A standard Raymond mill is sufficient to meet the requirements

Medical-grade/high-end cosmetic raw materials (above 300 mesh) : A turbine classifier is required to precisely control the particle size

- Humidity is key. Choose the right one to prevent clogging first

The moisture content of raw materials directly affects the stability of production. It is essential to make targeted choices:

Raw material moisture content ≤8% : Conventional Raymond mills can operate stably

If the moisture content of the raw material is greater than 8%, a model with a hot air system must be selected; otherwise, the risk of material blockage increases by 70%