Chalk is an amorphous limestone, the main component of which is calcium carbonate, and is usually white. It is mainly formed due to the deposition of red algae fossils and has the characteristics of being soft, loose and porous. Chalk is widely used in industry. It was once one of the main materials for making chalk and was also used as an important plastering material in construction.

| Property | Description |

|---|---|

| Product name | Calcium carbonate |

| Common name | Chalk |

| Molecular formula | CaCO₃ |

| Molecular weight | 100.09 g/mol |

| Type | Amorphous limestone |

| Crystal system | Amorphous (non-crystalline) |

| Appearance | Fine white powder or soft rock |

| Main uses | Rubber industry, coating industry, plastic industry, paper industry, ink industry, etc. |

Chalk crusher

As a low-hardness mineral, chalk is crushed by the periodic reciprocating motion of the movable jaw plate against the fixed jaw plate. The equipment has a deep crushing chamber and no dead zone, which improves the feeding capacity and output; the discharge port has a wide adjustment range to meet the production needs of different users. In addition, the single machine saves 15% to 30% energy, and the system saves more than double the energy. It has the characteristics of no noise and stable production, and can effectively crush chalk, laying the foundation for subsequent processing.

| Model | Max Feed Size (mm) | Discharge Range (mm) | Capacity (t/h) | Power (kw) | Dimensions (mm) |

|---|---|---|---|---|---|

| PE250×400 | 210 | 20-80 | 5-20 | 15 | 1450×1315×1296 |

| PE400×600 | 350 | 40-100 | 15-65 | 30 | 1700×1732×1653 |

| PE500×750 | 425 | 50-100 | 45-110 | 55 | 2035×1912×2000 |

| PE600×900 | 500 | 65-140 | 90-180 | 55-75 | 2290×2206×2370 |

| PE750×1060 | 630 | 80-160 | 110-320 | 110 | 2655×2302×3110 |

| PE900×1200 | 750 | 100-200 | 200-400 | 132 | 3380×2870×3330 |

| PE1000×1200 | 800 | 100-200 | 250-500 | 132 | 3480×2870×3330 |

| PE1200×1500 | 1020 | 150-300 | 400-800 | 180-220 | 4200×3750×3820 |

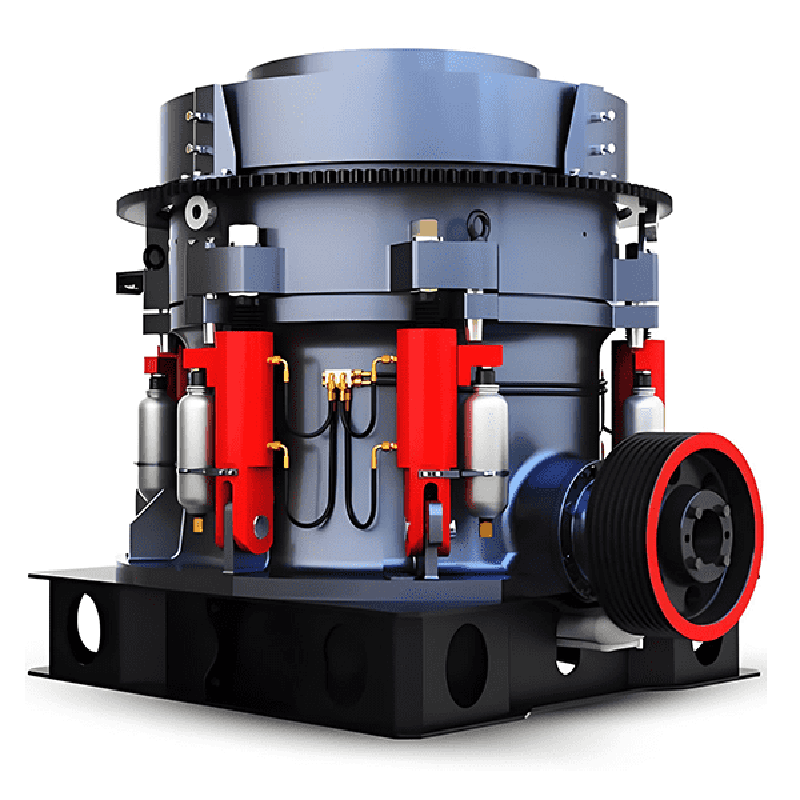

Cone crusher

Cone crusher is suitable for crushing medium-hard ores and rocks, and can also achieve good crushing of low-hardness materials such as chalk. Its advantages are special intergranular lamination crushing, production in a constant discharge area, large rated power and throughput, reliable structure, high production efficiency, convenient adjustment, and economical use. In addition, when not processing chalk, this equipment can also be used to crush minerals with medium hardness or above, such as limestone, and is one of the optional equipment for crushing chalk.

| Model | Cavity Size (Coarse/Fine) |

Max Feed Size (mm) |

Min Discharge Size (mm) |

Capacity (t/h) |

Power (kw) |

|---|---|---|---|---|---|

| HPT100 | C1 | 140 | 19 | 50-140 | 90 |

| C2 | 100 | 13 | 50-140 | 90 | |

| M | 70 | 9 | 50-140 | 90 | |

| F1 | 50 | 9 | 50-140 | 90 | |

| F2 | 20 | 6 | 50-140 | 90 | |

| HPT200 | C2 | 185 | 19 | 90-250 | 160 |

| M | 125 | 16 | 90-250 | 160 | |

| F1 | 95 | 13 | 90-250 | 160 | |

| F2 | 75 | 10 | 90-250 | 160 |

Impact crusher

The impact crusher crushes chalk with the help of impact energy. It has the characteristics of large feed inlet, high crushing chamber, and less stone powder in the product. It can crush the material on site, saving construction investment for users. In terms of components, it adopts high-strength and wear-resistant combined hammer head, with reinforcing ribs at the connection of the hammer head and widened width at the striking end, which enhances the strength of the hammer head, thereby improving the service life and safety of the hammer head, providing users with the possibility of reducing expenses; the whole machine has a light and reasonable structural design, and the quality is reliable and stable, and the chalk crushing effect is good. Therefore, the impact crusher is also one of the optional chalk crushing equipment.

Product Parameters

| Model | Specification (mm) |

Feed Opening Size (mm) |

Max Feed Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimensions (L×W×H) (mm) |

|---|---|---|---|---|---|---|

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 300-800 | 6P 630-710 | 4400×3866×4009 |