I. Petroleum Coke: An Underestimated Industrial Treasure

Petroleum coke is a key by-product of deep processing of crude oil. It is formed by cracking and coking vacuum residue oil at 500-550℃. It appears as black blocks, is hard in texture and has a metallic luster. Its honeycomb-like pore structure endows it with excellent properties.

Its carbon content is 90% to 97%, and its calorific value is 1.5 to 2 times that of coal. It is an excellent fuel for industrial combustion assistance in glass furnaces, boilers, etc.

In the metallurgical field, high-quality petroleum coke, after processing, is made into graphite electrodes or pre-baked anodes for electrolytic aluminum, which directly affects the efficiency of steelmaking and the quality of aluminum products.

In the chemical industry, it can be used as raw materials such as silicon carbide and carbon fiber to support the development of industries like abrasives and ceramics.

Its high carbon and high calorific value characteristics make it a core material in multiple fields, and technological progress is continuously unlocking its value.

II.The precise breakthrough of Shanghai Cronus

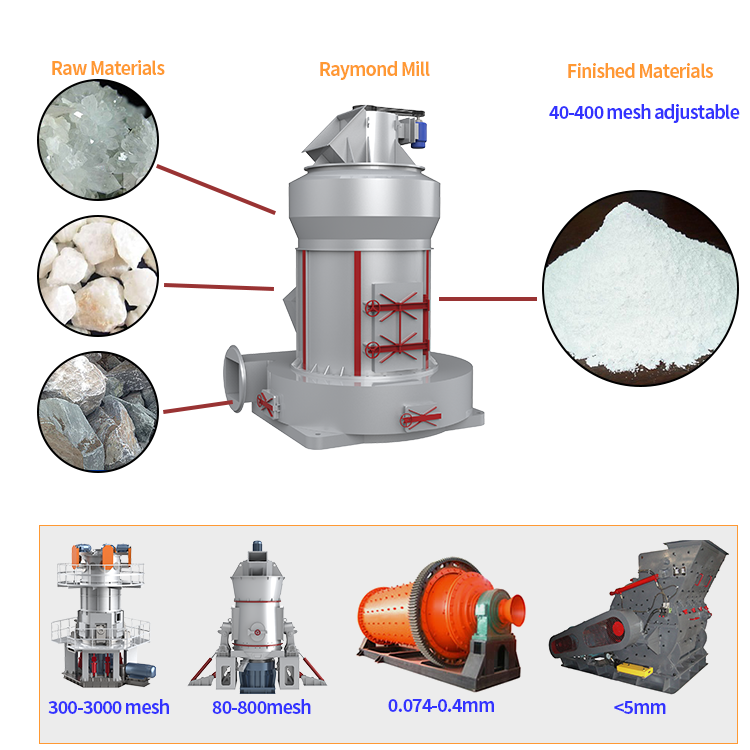

In response to the high hardness and porous nature of petroleum coke, which is prone to agglomeration, Shanghai Cronus customizes a dedicated Raymond mill to fundamentally meet the processing requirements.

The grinding rollers and grinding rings of the equipment are made of special wear-resistant materials, and the strong grinding pressure generated by centrifugal force is suitable for high hardness. Optimize the air duct design to prevent powder agglomeration and enhance grinding efficiency.

Adopting a closed-loop intelligent powder-making process of "grinding - screening - re-grinding", the entire process operates efficiently.

After the materials are subjected to high-pressure grinding in the grinding chamber, the strong air flow in the air ring screens the 200-mesh qualified powder. The coarse particles automatically fall back for re-grinding, forming a closed-loop processing.

This process ensures that the finished products are uniform, pure and free of impurities, while enhancing production efficiency and providing core support for stable operation. The equipment continuously and stably outputs a production capacity of 10-12 tons per hour. The fineness of 200 mesh is precisely controllable, and there are very few faults and shutdowns, significantly reducing maintenance costs.

High efficiency and low consumption: Under high-yield conditions, energy consumption is lower than the industry average, saving 20% of energy costs annually.

Stable and reliable: The equipment maintains high stability, reducing downtime losses.

Environmentally friendly and high-quality: Dust and noise standards are met, and the finished products are uniform without impurities, meeting the demands of high-end fields.

The value of refined processed petroleum coke doubles: making pre-baked anodes boosts electrolytic aluminum production capacity and reduces costs. Replace heavy oil to reduce costs and emissions for glass furnaces.

As a core carbon source for silicon carbide, it supports the development of industries such as abrasives and ceramics. The Cronus solution in Shanghai achieves a win-win situation of high-value resource utilization and green transformation.