The energy-saving ball mill developed by Shanghai Cronus Co., Ltd. has a wide range of applications and can grind over a hundred kinds of ores such as limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, quartz stone and bentonite. It can be used for processing various materials such as calcium carbonate crushing, gypsum powder processing, desulfurization in power plants, non-metallic mineral powder making and coal powder preparation.

The following is a brief introduction to the working principle of the ball mill

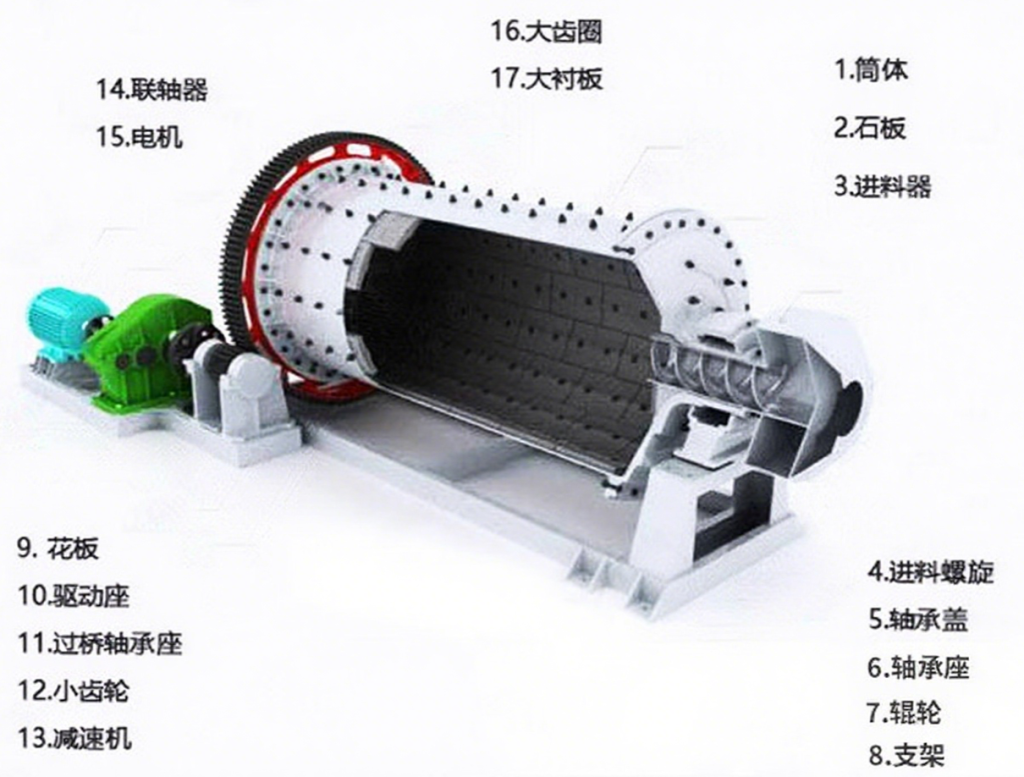

The selection is based on the particle size of the material to be ground. The material is fed into the cylinder through the hollow shaft at the feeding end of the ball mill. When the ball mill cylinder rotates, the grinding media, due to the effects of inertia, centrifugal force and friction, adhere to the liner of the cylinder and are carried away by the cylinder. When they are carried to a certain height, they are thrown off due to their own gravity. The falling grinding media, like projectiles, crush the materials inside the cylinder.

The materials are evenly fed into the first chamber of the mill through the feeding device and the hollow shaft screw. Inside this chamber, there are step liners or corrugated liners, and various specifications of steel balls are loaded. As the cylinder rotates, the centrifugal force is generated to lift the steel balls to a certain height and then they fall, exerting impact and grinding effects on the materials. After the materials are roughly ground in the first bin, they pass through a single-layer partition plate into the second bin, which is lined with flat plates and contains steel balls to further grind the materials. The powder is discharged through the discharge grate, completing the grinding operation.

During the rotation of the cylinder, the grinding media also slide off. During the sliding process, they exert a grinding effect on the materials. To effectively utilize the grinding effect, when grinding materials with a particle size of approximately 20 mesh, the grinding cylinder is divided into two sections by partition plates, thus forming a double compartment. When the materials enter the first compartment, they are crushed by steel balls. When they enter the second compartment, the steel sections grind the materials. The finely ground and qualified materials are discharged from the hollow shaft at the discharge end. When grinding materials with small feed particles, such as sand No. 2 slag and coarse fly ash, the grinding cylinder does not need to be equipped with partitions and can become a single-chamber cylinder mill. The grinding media can also be steel segments.

Raw materials are fed into a hollow cylinder through a hollow shaft neck for grinding. The cylinder is filled with grinding media of various diameters (such as steel balls, steel rods or gravel, etc.). When the cylinder rotates at a certain speed around the horizontal axis, the medium and raw materials inside the cylinder, under the action of centrifugal force and friction, reach a certain height along with the cylinder. When their own weight is greater than the centrifugal force, they will be thrown off the inner wall of the cylinder and fall or roll down, and the ore will be crushed due to the impact force. Meanwhile, during the rotation of the mill, the sliding motion between the grinding media also exerts a grinding effect on the raw materials. The ground material is discharged through the hollow shaft neck.