What are the advantages of a marble grinding mill?

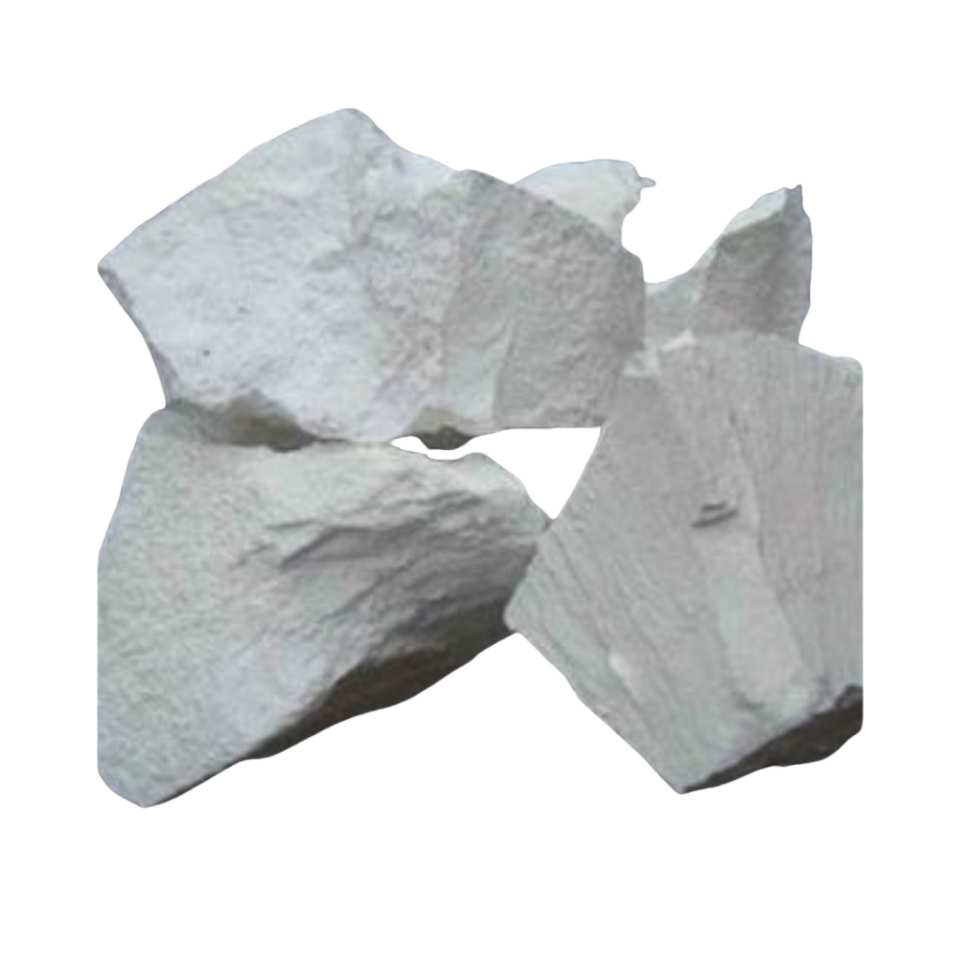

A marble grinding mill is a specialized device designed to process hard minerals like marble into fine powder. It plays a crucial role across various industries including construction, chemicals, metallurgy, and agriculture. Through its advanced design and efficient operation, the marble grinding mill brings multiple advantages to production processes and end applications. High Powder Fineness […]

- Processing Material:

- Output:

- Feed Particle Size:

- Discharge Particle Size:

A marble grinding mill is a specialized device designed to process hard minerals like marble into fine powder. It plays a crucial role across various industries including construction, chemicals, metallurgy, and agriculture. Through its advanced design and efficient operation, the marble grinding mill brings multiple advantages to production processes and end applications.

High Powder Fineness

One of the standout benefits of a marble grinding mill is its ability to produce fine and uniform marble powder. The micron-level fineness achieved allows for broader and more efficient application of marble in various fields. The high-quality powder is essential in producing smooth finishes in construction and consistent formulas in chemical manufacturing.

High Production Capacity

Marble grinding mills are engineered for efficiency. The high-speed rotation of grinding discs and rollers ensures that large volumes of marble can be processed in a shorter amount of time. This increases productivity and makes the equipment suitable for both small-scale and large-scale production environments.

Energy-Saving and Environmentally Friendly

Modern marble grinding mills adopt new types of grinding components such as energy-efficient discs and rollers. These advancements not only reduce power consumption but also contribute to a cleaner production process. Many of these mills meet current environmental standards, making them an ideal choice for sustainable operations.

Easy Operation and Low Maintenance

Another key advantage is the user-friendly design of the marble grinding mill. Its simple structure allows for straightforward operation, making it accessible even for operators with minimal training. Additionally, its robust build ensures long-term operation with minimal maintenance, reducing downtime and operational costs.

Versatile Applications of Marble Powder

The fine marble powder produced by these mills serves a wide range of industries:

- Building Materials: Used in decorative flooring, wall cladding, and architectural elements, marble powder provides a polished and durable finish.

- Chemical Industry: Employed in the production of paints, rubber, plastics, and paper, it serves as a reliable raw material.

- Industrial Use: Incorporated into the manufacture of artificial stone, ceramics, and glass, marble powder is a valuable ingredient in many industrial processes.

- Agriculture: When processed to specific particle sizes, marble powder can be applied as a soil conditioner to adjust pH levels and improve soil health, thereby promoting crop growth.

Choosing the Right Marble Grinding Mill

When selecting a marble grinding mill, it is important to consider the physical properties of the marble and choose appropriate grinding discs and rollers. Ensuring equipment safety and troubleshooting operational issues promptly will help maintain smooth and efficient production.

In conclusion, a marble grinding mill is an essential piece of equipment for turning raw marble into a valuable and versatile powder. Its advantages in precision, efficiency, sustainability, and ease of use make it a preferred choice across multiple sectors. For those seeking to optimize their marble processing operations, choosing the right grinding mill is a crucial step toward achieving consistent quality and productivity.