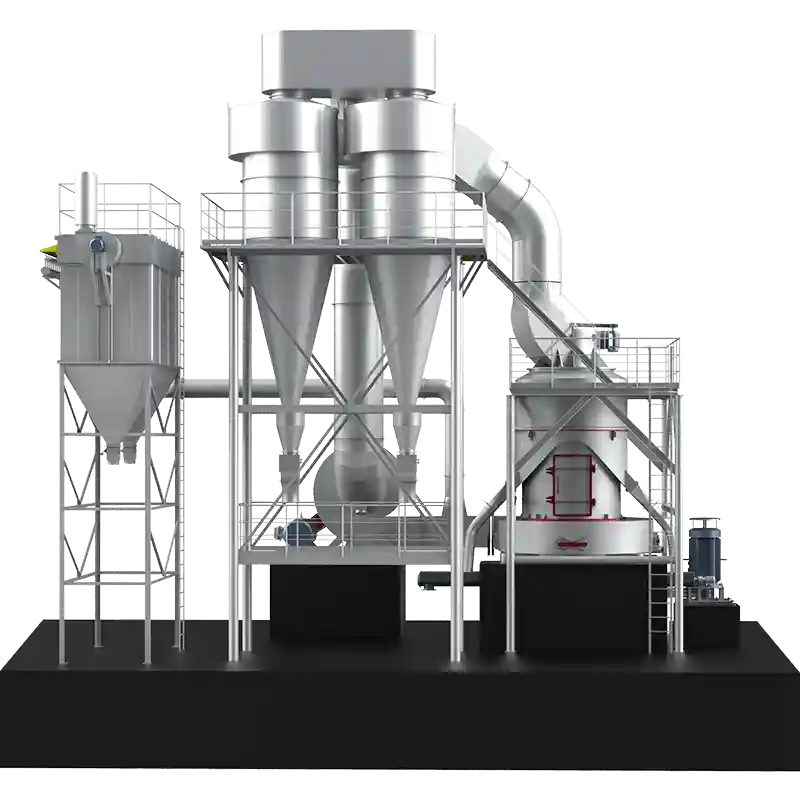

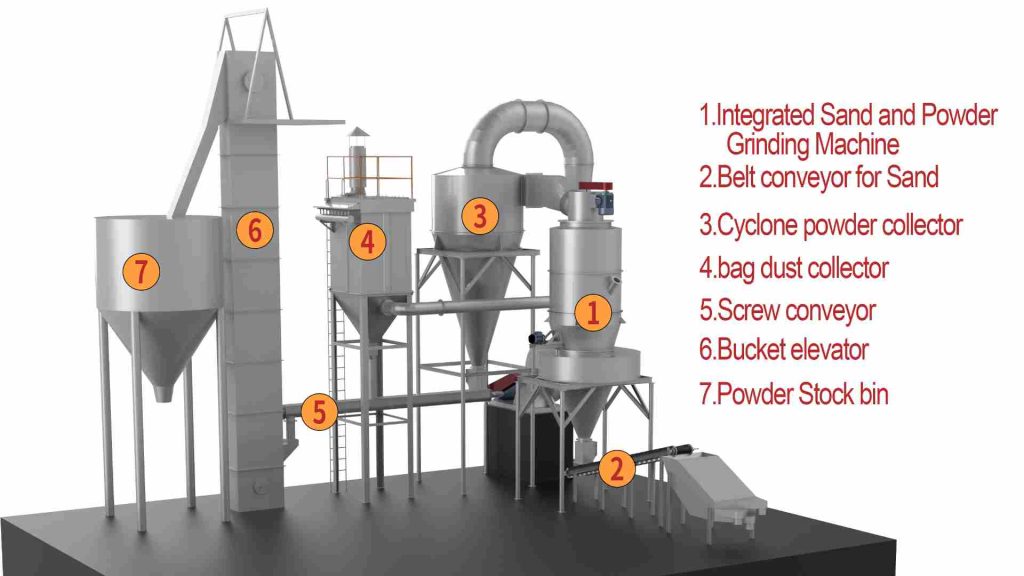

Integrated Sand and Powder Grinding Machine

Integrated Sand and Powder Grinding Machine This machine is an optimized and improved version of Raymond Mill. It offers dual functionality with no additional energy costs. Key Features: Simultaneous production of fine sand and fine powder Energy consumption remains unchanged from standard operation Equivalent to producing two products with the same power consumption Total output […]