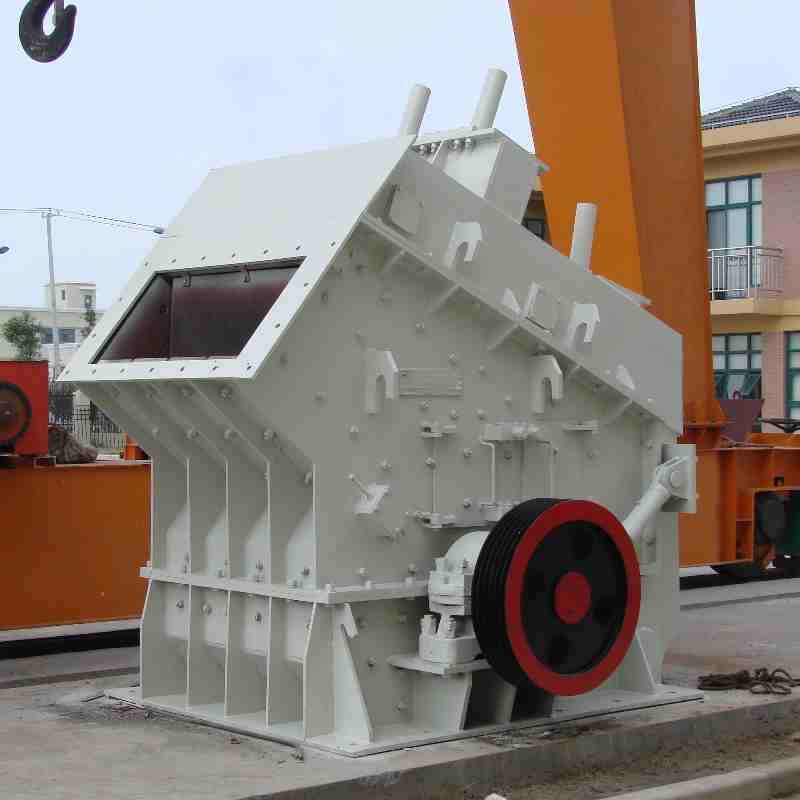

Impact crushers are widely used reduced-size machines designed to crush various materials, including rocks, concrete and recycled waste. It strikes these materials with a high-speed rotating hammer or punch, causing them to shatter upon impact. This mechanism makes impact crushers particularly effective in production.

This article will explore the functions, types, applications and advantages of impact crushers, thereby providing a comprehensive understanding of their role in modern material processing.

Key applications of impact crushers

Total output

Crushing quarry rocks: Impact crushers are typically used to crush various quarry rocks, such as limestone and granite. These materials are crushed into uniform sizes suitable for construction applications, such as road base and concrete aggregates.

Output control: Many impact crushers are equipped with adjustable baffles and screens, enabling operators to precisely control the size of the final product. This flexibility is crucial for meeting the requirements of specific projects and ensuring consistent quality.

Recycling

Handling demolition waste: Impact crushers are adept at handling demolition waste, including concrete, asphalt and bricks. By crushing these materials into reusable sizes, impact crushers contribute to sustainable construction practices.

C&D recycling plants: They are particularly suitable for construction and demolition (C&D) recycling facilities, where they help reduce landfill waste and promote a circular economy.

Mining and minerals

Crushing softer ores: In the mining industry, impact crushers are used

Limitations: Although it is effective for relatively soft materials, impact crushers are not very suitable for extremely hard materials with high silica content, etc. In this case, other types of crushers, such as jaw crushers or cone crushers, might be more suitable.

Industrial materials

Crushing glass and ceramics: Impact crushers can also be used to crush industrial materials such as glass, ceramics and specific metals. This processing is crucial for recycling and reprocessing these materials to produce new products.